-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Efficient Techniques for Bending Steel Tubes in Metal Fabrication Projects

The Versatility and Importance of Steel Tube Benders

In the world of metalworking, the ability to manipulate materials into precise shapes is a fundamental skill. One of the essential tools for this task is the steel tube bender. This piece of equipment is crucial for industries that require the bending of steel tubes for various applications, from construction to automotive manufacturing.

Understanding Steel Tube Benders

Steel tube benders are specialized machines designed to bend steel tubes into specific configurations without collapsing or deforming the material. They come in various types, including manual benders, hydraulic benders, and CNC (Computer Numerical Control) benders. Each type serves distinct purposes based on the complexity of the bending tasks and the volume of production.

1. Manual Tube Benders These are the simplest forms of tube benders, requiring manual effort to bend the metal. They are usually employed in small workshops or by hobbyists who need to bend tubes occasionally. Manual benders are cost-effective and relatively easy to use, making them ideal for simple, low-volume tasks.

2. Hydraulic Tube Benders For more demanding jobs, hydraulic benders provide the necessary power to bend thicker tubes or achieve more complex angles. Utilizing hydraulic pressure, these machines can exert significant force, allowing for clean and precise bends. They are commonly used in fabricating exhaust systems and architectural structures where durability is essential.

3. CNC Tube Benders The most advanced form of tube bending equipment, CNC benders, use computer programming to control the bending process. This allows for high levels of precision and repeatability, making them perfect for mass production. Industries that require intricate designs, such as aerospace or automotive manufacturing, often rely on CNC benders to meet stringent specifications.

Applications of Steel Tube Benders

The applications of steel tube benders are vast and varied. In construction, steel tubes are commonly used for scaffolding, handrails, and structural supports. Precision in bending is critical to ensure that these components fit together seamlessly, providing safety and support in complex structures.

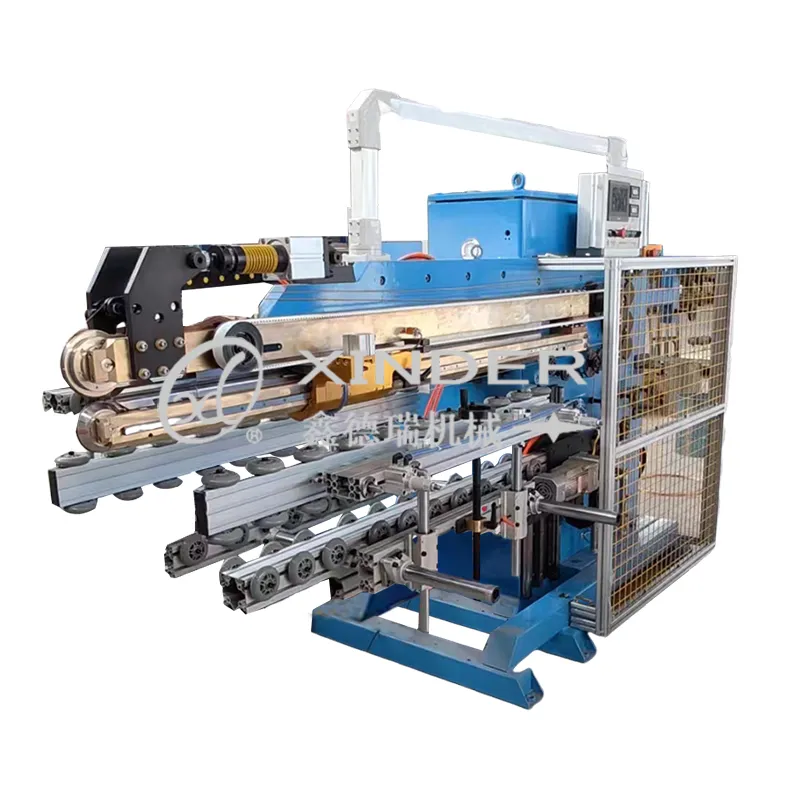

steel tube bender

In the automotive industry, steel tube benders are essential for manufacturing parts like roll cages, exhaust headers, and chassis components. These parts must not only be strong but also lightweight to improve vehicle performance. Here, the ability to bend steel tubes accurately is crucial to maintain the integrity and safety of the vehicle.

Additionally, industries like furniture manufacturing and art installations also benefit from tube bending. Designers can create intricate shapes and forms that enhance both functionality and aesthetics. Here, the aesthetic aspect of the bend is often just as important as the structural integrity.

The Benefits of Using Steel Tube Benders

Using steel tube benders comes with numerous advantages. Foremost, they allow for the creation of complex shapes that would be impossible to achieve otherwise. This capability can lead to innovative designs and applications that enhance performance or aesthetic appeal.

Moreover, tube bending can help save material and reduce waste. By bending steel tubes instead of cutting them into smaller pieces, manufacturers can maintain more of the raw material, which is not only economical but also environmentally friendly.

Additionally, modern tube benders are equipped with safety features and controls that minimize the risk of accidents and improve overall work efficiency. Automation in CNC benders means that once a design is inputted, the machine can produce parts with minimal human intervention, reducing the potential for error.

Conclusion

Steel tube benders are indispensable tools in a wide range of industries, providing the necessary precision and versatility to shape and manipulate metal. Whether for crafting building supports, automotive components, or artistic creations, the significance of tube benders cannot be overstated. As technology continues to evolve, the capabilities of these machines will expand, providing unprecedented opportunities for innovation in metalworking. The steel tube bender is not just a tool; it is a gateway to creativity and engineering excellence.

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024