-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

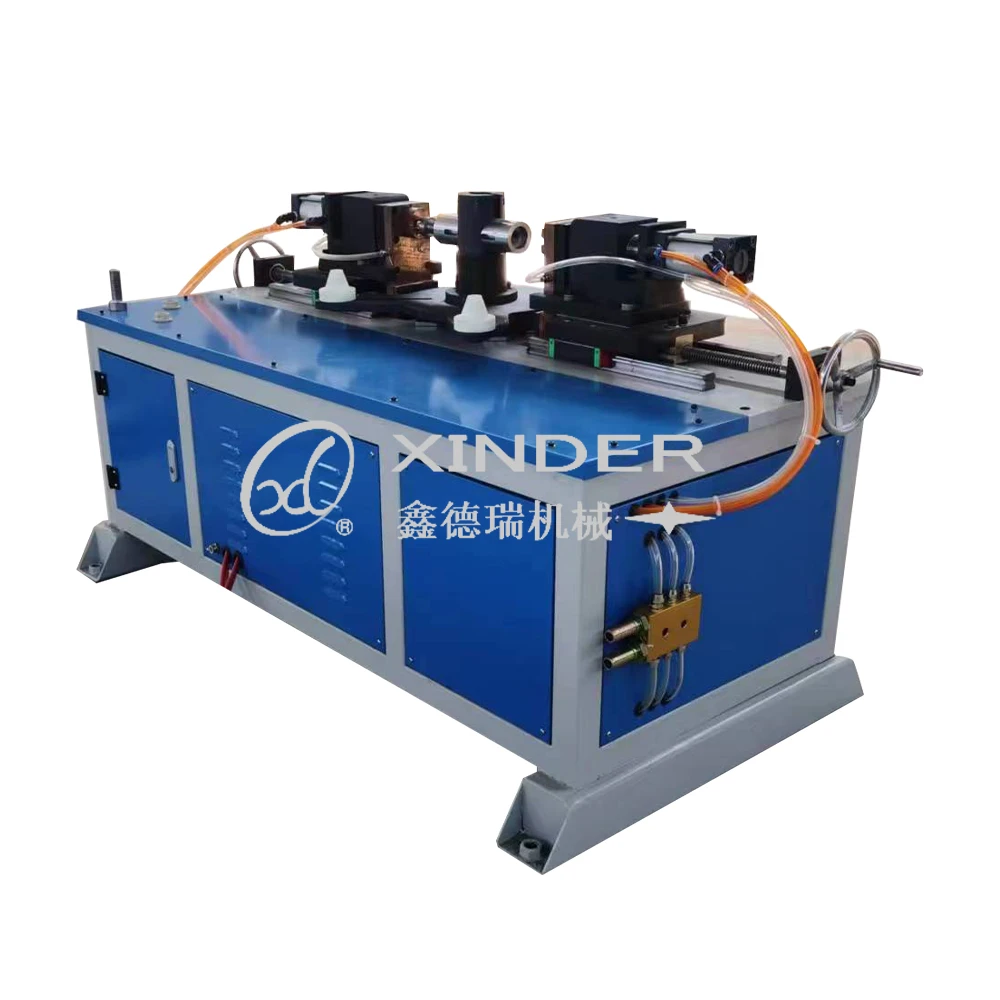

ss sheet bending machine

Understanding Sheet Bending Machines A Comprehensive Overview

Sheet bending machines are essential tools in modern manufacturing and metalworking industries, playing a crucial role in the formation of sheet metal components. These machines are designed to bend flat sheets of metal into various shapes and angles, making them indispensable in the production of everything from automotive parts to architectural elements. This article delves into the various aspects of sheet bending machines, including their types, working mechanisms, applications, and advancements in technology.

Types of Sheet Bending Machines

There are several types of sheet bending machines, each suited for different applications and materials. The most common types include

1. Press Brakes One of the most widely used sheet bending machines, press brakes use a punch and die mechanism to create bends in metal sheets. They can handle various thicknesses and widths, making them versatile in both large-scale production and small operations.

2. Roll Benders These machines use three rollers to gradually bend the sheet metal into circular shapes or arcs. Roll benders are perfect for creating cylindrical components, such as pipes and tanks.

3. Box and Pan Brakes Also known as finger brakes, these machines allow for more complex bending tasks, particularly for boxes and trays. They feature adjustable clamping fingers, enabling the bending of multiple parts simultaneously.

4. Hydraulic Bending Machines Utilizing hydraulic power, these machines can exert significant force to bend thick sheets of metal efficiently. They are highly effective for heavy-duty applications and provide greater control over the bending process.

Working Mechanisms

ss sheet bending machine

The operation of sheet bending machines typically involves placing a metal sheet between a punch and a die. The punch descends to apply force on the sheet, bending it around the die to the desired angle. Advanced models feature CNC (Computer Numerical Control) technology, allowing for precise control over the bending process. This is particularly useful for intricate designs and tight tolerances, ensuring consistent output quality.

In addition to CNC, modern sheet bending machines also leverage hydraulic and pneumatic systems for increased power and efficiency. These advancements have led to higher production rates and improved safety measures, as operators can oversee the process with less manual intervention.

Applications Across Industries

Sheet bending machines find application in a wide range of industries. In the automotive sector, they contribute to the fabrication of body panels, frames, and supports. The construction industry relies on these machines for producing elements like brackets, beams, and custom metal parts. Moreover, the aerospace industry uses sheet bending technology to create lightweight, strong components essential for aircraft design.

Technological Advancements

In recent years, the sheet bending machine market has seen significant technological advancements. Features such as programmable logic controllers (PLCs) and advanced software integration have streamlined operations, making it easier for workers to design and execute complex bending tasks. Additionally, innovations in materials, such as high-strength alloys and lighter metals, have expanded the capabilities and applications of sheet bending machines.

Conclusion

Sheet bending machines are vital in shaping the future of manufacturing and metal processing. As industries continue to demand precision and efficiency, these machines will evolve, incorporating the latest technologies to meet the challenges ahead. Whether it's producing simple brackets or intricate designs, the importance of sheet bending machines in modern production cannot be overstated. Their ability to transform flat metal sheets into functional components will remain an integral part of countless industries for years to come.

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024