-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Xan . 14, 2025 11:29

Back to list

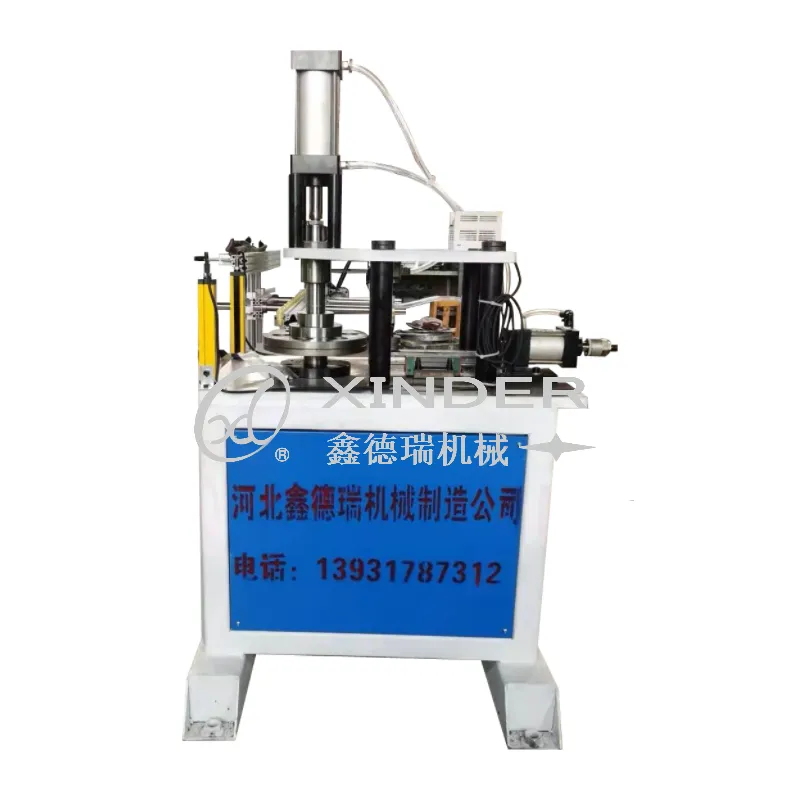

Hydraulic Bending Machine

Navigating the world of tools and machinery, the stainless steel sheet bender stands out as a vital component in modern manufacturing and construction industries. This machine offers unparalleled precision and versatility, catering to a plethora of projects from architectural structures to intricate designs. To truly understand its impact, one must delve into its design, application, and the expertise required to operate it effectively.

Importantly, the trustworthiness of a stainless steel sheet bender is reflected in its compliance with industry standards and certifications. Machines that meet or exceed these benchmarks assure stakeholders of their reliability and safety. These standards are curated by authoritative industry bodies, emphasizing quality control and operational safety. From an economic perspective, stainless steel sheet benders contribute significantly to cost savings and operational efficiency. By allowing precise bending of steel sheets in-house, companies can reduce dependency on external fabricators. This not only cuts down on outsourcing costs but also shortens production timelines, delivering faster project completion and client satisfaction. Furthermore, the ability to produce complex bends and designs can distinguish a firm as an industry leader, enhancing its competitive edge. In conclusion, the stainless steel sheet bender is an indispensable tool in any manufacturing or construction setting. Its successful integration into production lines hinges on a blend of advanced technology, skilled operation, and strategic investment. As industries continue to evolve, staying updated with the latest trends and innovations in sheet bending technology will be crucial in maintaining authority and trust in the competitive landscape. Adopting a stainless steel sheet bender isn't just about embracing a machine; it's about investing in precision, efficiency, and unparalleled quality assurance.

Importantly, the trustworthiness of a stainless steel sheet bender is reflected in its compliance with industry standards and certifications. Machines that meet or exceed these benchmarks assure stakeholders of their reliability and safety. These standards are curated by authoritative industry bodies, emphasizing quality control and operational safety. From an economic perspective, stainless steel sheet benders contribute significantly to cost savings and operational efficiency. By allowing precise bending of steel sheets in-house, companies can reduce dependency on external fabricators. This not only cuts down on outsourcing costs but also shortens production timelines, delivering faster project completion and client satisfaction. Furthermore, the ability to produce complex bends and designs can distinguish a firm as an industry leader, enhancing its competitive edge. In conclusion, the stainless steel sheet bender is an indispensable tool in any manufacturing or construction setting. Its successful integration into production lines hinges on a blend of advanced technology, skilled operation, and strategic investment. As industries continue to evolve, staying updated with the latest trends and innovations in sheet bending technology will be crucial in maintaining authority and trust in the competitive landscape. Adopting a stainless steel sheet bender isn't just about embracing a machine; it's about investing in precision, efficiency, and unparalleled quality assurance.

Next:

Latest News

-

The Rise of Laser Welding in Global Manufacturing: Spotlight on China’s Competitive EdgeNewsJun.05,2025

-

The Power of Precision: Exploring the Role of Automatic Seam Welding Machines in Modern ManufacturingNewsJun.05,2025

-

The Essential Guide to Can Welding Machines: Revolutionizing the Packaging IndustryNewsJun.05,2025

-

Resistance Welding Equipment: A Smart Investment for Industrial ManufacturingNewsJun.05,2025

-

Precision Welding for Modern Manufacturing: The Rise of Automatic Seam Welding MachinesNewsJun.05,2025

-

Laser Welding for Stainless Steel: The Precision Edge in Modern Metal FabricationNewsJun.05,2025

-

The Modern Evolution of Barrel Production: Technology, Machines, and Market PricingNewsMay.22,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024