-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

helmi . 20, 2025 06:30

Back to list

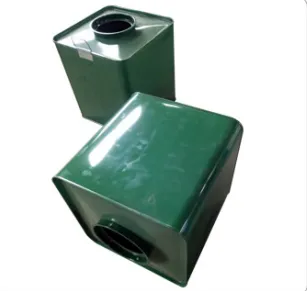

automatic seam welding machine

Straight seam welding machines are at the forefront of modern manufacturing, providing precise and efficient solutions for industries requiring longitudinal welds. These machines have become an integral component for sectors such as automotive, construction, and pipeline manufacturing due to their ability to streamline production processes while maintaining high-quality output.

Trust in straight seam welding machines also stems from their demonstrable impact on quality control. Advanced models are equipped with sensors and data analytics tools that monitor weld quality in real time. These integrated systems offer immediate feedback, enabling operators to adjust parameters on the fly, thereby ensuring each weld meets stringent standards. Moreover, these machines are integral in meeting the increased demand for eco-friendly production processes. Many modern models incorporate energy-efficient technologies that reduce consumption without sacrificing performance. This feature is not only economically beneficial but also aligns with global efforts to reduce industrial carbon footprints. In the competitive landscape of product manufacturing, the role of straight seam welding machines is indisputable. Companies leveraging these machines experience significant improvements in efficiency, product consistency, and overall output. Consequently, they gain a competitive edge, meeting market demands with precision and speed that traditional welding methods simply cannot match. Straight seam welding technology represents the convergence of mechanical expertise and innovative engineering. As industries continue to evolve, so too will these machines, offering even more advanced capabilities. Their future likely includes further integration with AI and machine learning to predict maintenance needs and optimize welding processes dynamically. In conclusion, straight seam welding machines are indispensable tools that align with the core principles of Experience, Expertise, Authoritativeness, and Trustworthiness. Their adoption is a testament to the value of incorporating cutting-edge technology into manufacturing processes, ensuring that businesses remain at the forefront of their industries while upholding the highest standards of quality and efficiency.

Trust in straight seam welding machines also stems from their demonstrable impact on quality control. Advanced models are equipped with sensors and data analytics tools that monitor weld quality in real time. These integrated systems offer immediate feedback, enabling operators to adjust parameters on the fly, thereby ensuring each weld meets stringent standards. Moreover, these machines are integral in meeting the increased demand for eco-friendly production processes. Many modern models incorporate energy-efficient technologies that reduce consumption without sacrificing performance. This feature is not only economically beneficial but also aligns with global efforts to reduce industrial carbon footprints. In the competitive landscape of product manufacturing, the role of straight seam welding machines is indisputable. Companies leveraging these machines experience significant improvements in efficiency, product consistency, and overall output. Consequently, they gain a competitive edge, meeting market demands with precision and speed that traditional welding methods simply cannot match. Straight seam welding technology represents the convergence of mechanical expertise and innovative engineering. As industries continue to evolve, so too will these machines, offering even more advanced capabilities. Their future likely includes further integration with AI and machine learning to predict maintenance needs and optimize welding processes dynamically. In conclusion, straight seam welding machines are indispensable tools that align with the core principles of Experience, Expertise, Authoritativeness, and Trustworthiness. Their adoption is a testament to the value of incorporating cutting-edge technology into manufacturing processes, ensuring that businesses remain at the forefront of their industries while upholding the highest standards of quality and efficiency.

Next:

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024