-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

tammi . 14, 2025 12:14

Back to list

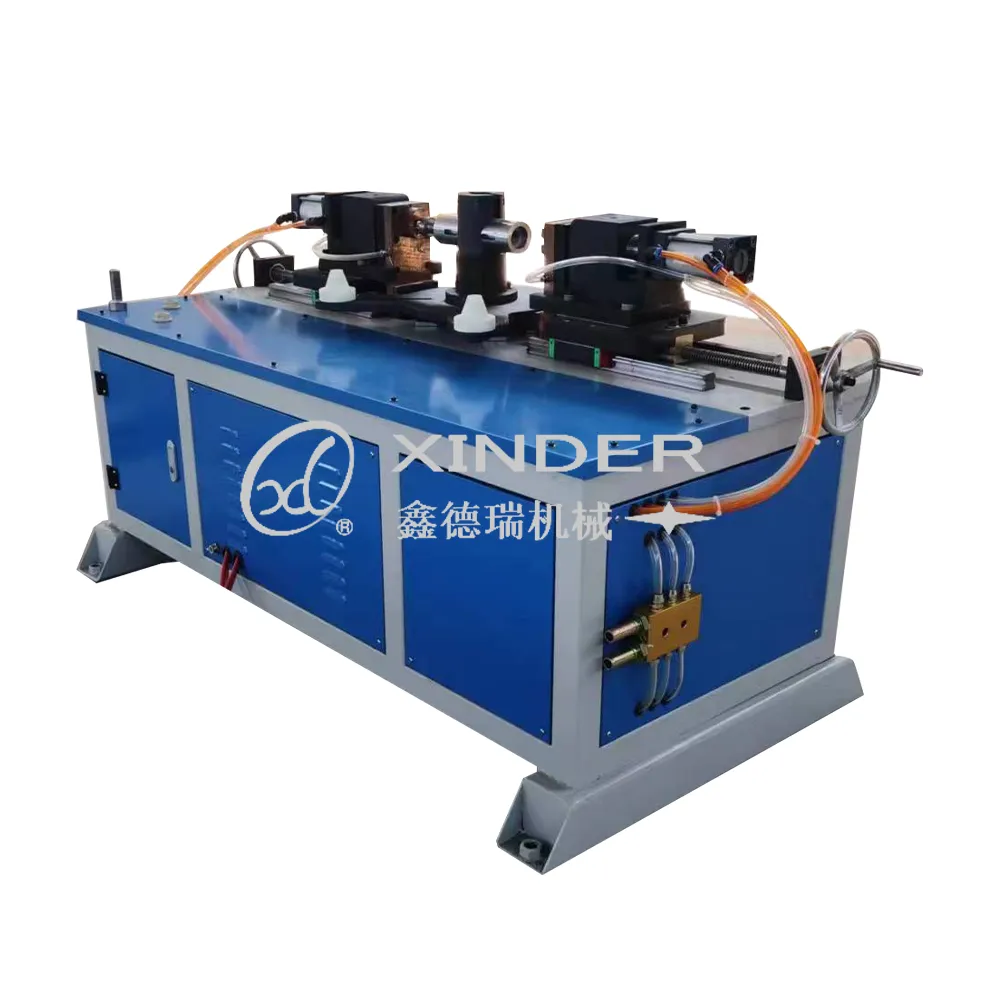

hydraulic bending machine for sale

Operating a bending machine requires not only technical expertise but also a keen understanding of the industry standards and best practices to ensure optimal performance and safety. This article delves into the nuanced process of operating a bending machine, highlighting real-world experiences and expert insights that underscore the complexities and intricacies involved.

A recognized authority in the field would advise that understanding the material properties is just as critical as understanding the machine itself. Different metals respond differently under stress; therefore, it's vital to select the appropriate machine settings. For instance, while bending aluminum requires less force due to its malleability, stainless steel demands more pressure to achieve a similar bend without causing fractures. Trust is built through consistent demonstration of reliability and competence. In an industrial setting, a bending machine operator's trustworthiness is reflected in their ability to deliver precise, defect-free products. This reliability is cultivated through continuous education and training, keeping abreast of technological advancements and emerging techniques in machine operation. Product innovation also plays a significant role in bending machine operations. As technological advancements continue to evolve, newer models of bending machines are introduced, offering enhanced performance capabilities. Operators are encouraged to familiarize themselves with these innovations, as staying ahead of trends not only improves operational efficiency but also enhances product quality and reduces waste. To summarize, bending machine operation is an intricate art that integrates experience, expertise, authority, and trustworthiness into every aspect of the process. Proficient operators are not just technically knowledgeable, but they also exhibit a mastery of machine handling, an uncompromising stance on safety regulations, and an ability to adapt to new technologies and methods. Such a holistic approach ensures not only the success of individual projects but also contributes to broader industry advancements. As we progress towards a future defined by precision and efficiency, operators equipped with these skills stand poised at the forefront of innovation and excellence in the bending machine domain.

A recognized authority in the field would advise that understanding the material properties is just as critical as understanding the machine itself. Different metals respond differently under stress; therefore, it's vital to select the appropriate machine settings. For instance, while bending aluminum requires less force due to its malleability, stainless steel demands more pressure to achieve a similar bend without causing fractures. Trust is built through consistent demonstration of reliability and competence. In an industrial setting, a bending machine operator's trustworthiness is reflected in their ability to deliver precise, defect-free products. This reliability is cultivated through continuous education and training, keeping abreast of technological advancements and emerging techniques in machine operation. Product innovation also plays a significant role in bending machine operations. As technological advancements continue to evolve, newer models of bending machines are introduced, offering enhanced performance capabilities. Operators are encouraged to familiarize themselves with these innovations, as staying ahead of trends not only improves operational efficiency but also enhances product quality and reduces waste. To summarize, bending machine operation is an intricate art that integrates experience, expertise, authority, and trustworthiness into every aspect of the process. Proficient operators are not just technically knowledgeable, but they also exhibit a mastery of machine handling, an uncompromising stance on safety regulations, and an ability to adapt to new technologies and methods. Such a holistic approach ensures not only the success of individual projects but also contributes to broader industry advancements. As we progress towards a future defined by precision and efficiency, operators equipped with these skills stand poised at the forefront of innovation and excellence in the bending machine domain.

Latest News

-

Understanding Resistance Welding: Equipment, Manufacturers, and PricingNewsMay.15,2025

-

Understanding Pneumatic Welding Machines: Types, Applications, and AdvantagesNewsMay.15,2025

-

Exploring Tube Benders: Types, Manufacturers, and ApplicationsNewsMay.15,2025

-

Exploring Metal Pipe Machines: Types, Functions, and ApplicationsNewsMay.15,2025

-

Exploring Laser Welding Machines: Key Manufacturers, Technology, and ApplicationsNewsMay.15,2025

-

Exploring Barrel Production Lines: Machines, Pricing, and Manufacturing ProcessNewsMay.15,2025

-

The Role of Steel Pipe Manufacturing Machines in Modern IndustriesNewsApr.18,2025

related products

-

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024 -

Automatic Rolling MachineSep . 14, 2024

Automatic Rolling MachineSep . 14, 2024