-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

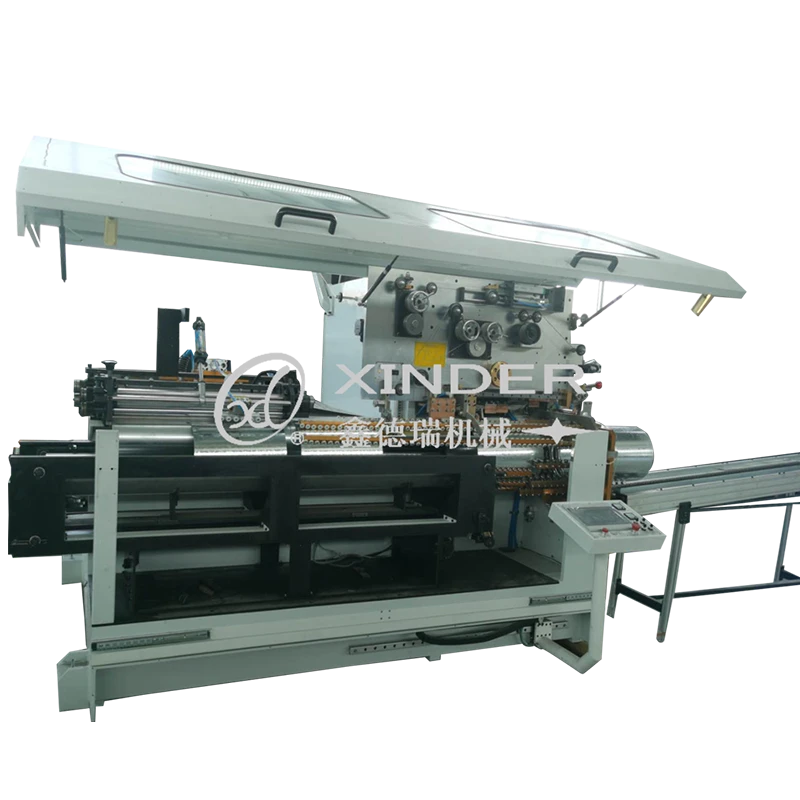

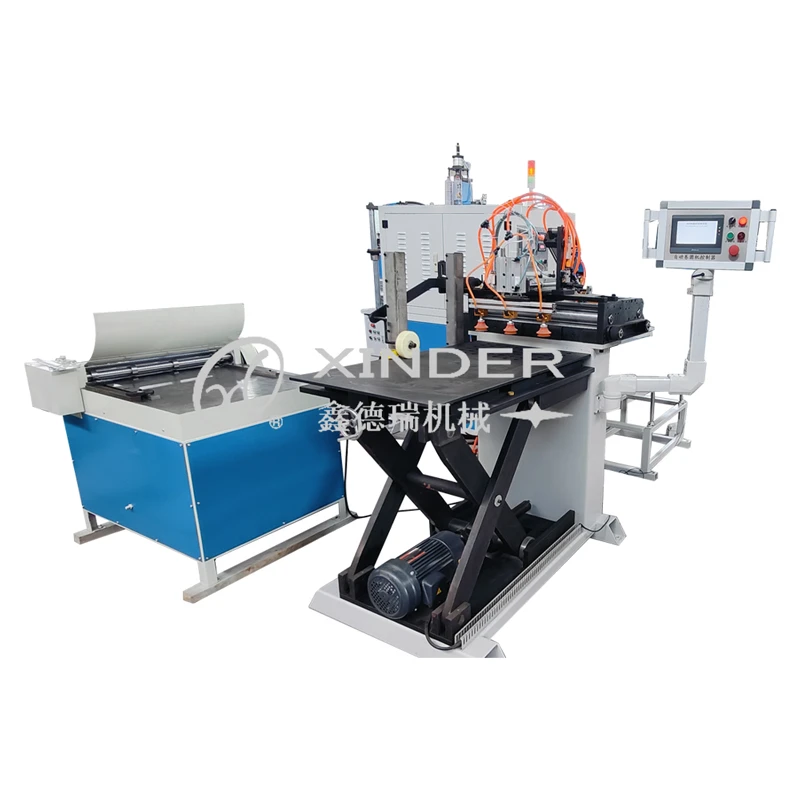

steel drum making machine

Steel drum making machines have revolutionized manufacturing efficiency in the packaging industry, offering unparalleled speed and precision in drum production. These machines are engineered to streamline the fabrication process for steel drums, ensuring durability and quality that meet industry standards. Built with advanced technology, they seamlessly integrate various production stages, from cutting and shaping the steel sheets to assembling and finishing the drums.

In the competitive landscape of industrial packaging, businesses must prioritize efficiency and quality to maintain their edge. Steel drum making machines are designed to address these demands. Their automation capabilities not only minimize human error but also significantly enhance production rates. By adopting these machines, manufacturers can ensure consistent product quality, which builds trust with consumers and partners alike.

One of the standout features of contemporary steel drum making machines is their adaptability. They come equipped with customizable modules that can be adjusted based on specific requirements, making them versatile for different drum sizes and specifications. This customization is crucial for manufacturers who serve various market segments. The machines also offer user-friendly interfaces and maintenance protocols, which reduce downtime and increase operational productivity.

From an expertise standpoint, these machines incorporate cutting-edge technology such as computerized numerical control (CNC) systems. This technology allows for precise control over cutting, bending, and welding processes. With CNC systems, manufacturers can achieve high precision that ensures the structural integrity of each drum, making them suitable for transporting hazardous and non-hazardous materials safely.

steel drum making machine

Authority in the field of industrial drum production is largely built on a foundation of reliable and innovative machinery. Manufacturers who invest in state-of-the-art drum making machines position themselves as leaders in the industry. Aligning with regulatory standards, these machines assure compliance and foster credibility. The integration of quality assurance protocols within these machines ensures that manufacturers consistently produce drums that meet international safety and quality certifications.

Such investments in technology also reflect a commitment to sustainability. Modern steel drum making machines not only optimize material use but also incorporate energy-efficient modes. These eco-friendly features reduce the carbon footprint of the manufacturing process, appealing to environmentally-conscious partners and clients. By championing green manufacturing practices, companies can both preserve the environment and meet the growing demand for sustainable products.

Trustworthiness in the realm of steel drum production is underscored by consistent performance and reliability. Customers look for manufacturers who can deliver products that offer superior security for transporting goods. Steel drum making machines, with their technological advancements, mitigate the risk of defects during transport. This assurance is critical for industries such as chemicals and pharmaceuticals where material integrity is non-negotiable.

Steel drum making machines, with their advanced features and capabilities, have set new benchmarks in the packaging industry. They ensure efficiency, adaptability, and compliance, all while fostering sustainability and trust. For businesses seeking to enhance their production lines, investing in these machines is a strategic move to bolster their market position and reputation.

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024