-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

فوریه . 18, 2025 00:27

Back to list

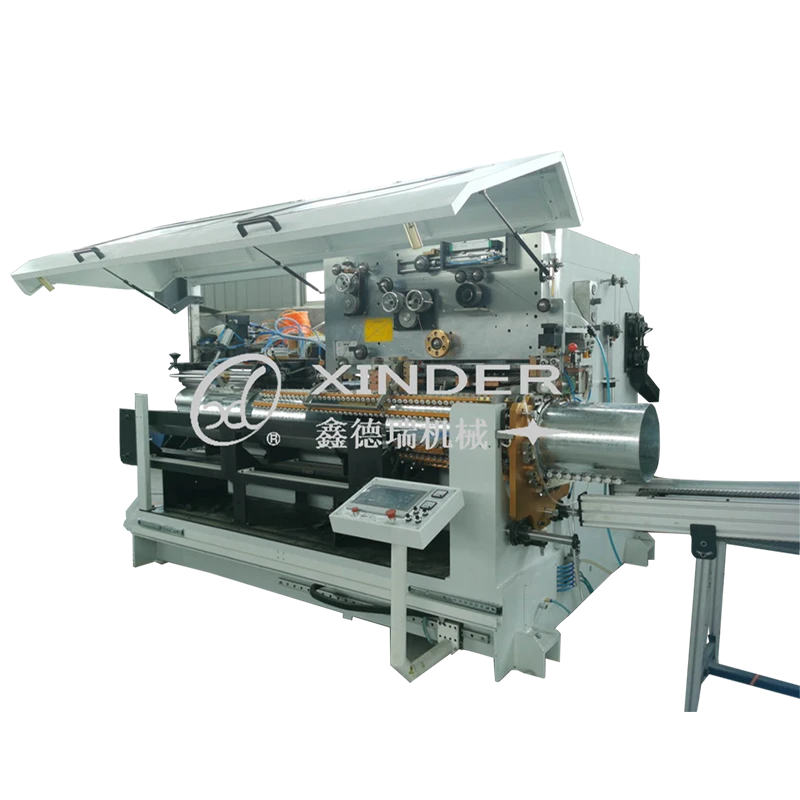

Fully Automatic Steel Barrel Straight Seam Laser Welding Machine

Round machines have revolutionized various industries, offering efficiency and precision that has reshaped production and functionality. Understanding the profound impact of these machines requires delving into their multifaceted applications, technical specifications, and the reliability they impart to professionals across sectors.

Beyond the apparent functional benefits, the reliability of round machines is anchored in their durable construction and the reduced need for frequent maintenance. Companies manufacturing these machines invest heavily in research and development to enhance their lifespan and operational efficiency. The combination of user expertise and manufacturing excellence solidifies the trustworthiness of round machines, as users rely on them for prolonged, flawless operations across various applications. Round machines' adaptation to technological advancements further enhances their authoritative appeal. Integration with digital interfaces and IoT technology means these machines can now offer real-time data analytics. This feature helps operators monitor performance, predict maintenance needs, and prevent unexpected downtimes. Such developments reflect an industry's appreciation for innovation, where round machines stand as a testament to progress, empowering users to achieve optimal output while minimizing costs and wastage. As an authoritative fixture in multiple industries, round machines embody the perfect blend of art and science. Their seamless operations are a product of state-of-the-art engineering principles, while their capacity to boost productivity reflects their indispensable role in modern-day production and manufacturing. Trust in these robust machines underscores their consistent performance, and as new technologies emerge, they are poised to integrate and enhance their capabilities further. For any professional or business contemplating the integration of round machines into their operations, recognizing their potential to transform and elevate productivity is imperative. The depth of expertise required to operate these machines cannot be understated, yet the rewards they deliver—quality, precision, and efficiency—establishes their unrivaled authority in the manufacturing and production worlds.

Beyond the apparent functional benefits, the reliability of round machines is anchored in their durable construction and the reduced need for frequent maintenance. Companies manufacturing these machines invest heavily in research and development to enhance their lifespan and operational efficiency. The combination of user expertise and manufacturing excellence solidifies the trustworthiness of round machines, as users rely on them for prolonged, flawless operations across various applications. Round machines' adaptation to technological advancements further enhances their authoritative appeal. Integration with digital interfaces and IoT technology means these machines can now offer real-time data analytics. This feature helps operators monitor performance, predict maintenance needs, and prevent unexpected downtimes. Such developments reflect an industry's appreciation for innovation, where round machines stand as a testament to progress, empowering users to achieve optimal output while minimizing costs and wastage. As an authoritative fixture in multiple industries, round machines embody the perfect blend of art and science. Their seamless operations are a product of state-of-the-art engineering principles, while their capacity to boost productivity reflects their indispensable role in modern-day production and manufacturing. Trust in these robust machines underscores their consistent performance, and as new technologies emerge, they are poised to integrate and enhance their capabilities further. For any professional or business contemplating the integration of round machines into their operations, recognizing their potential to transform and elevate productivity is imperative. The depth of expertise required to operate these machines cannot be understated, yet the rewards they deliver—quality, precision, and efficiency—establishes their unrivaled authority in the manufacturing and production worlds.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024