-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

فوریه . 17, 2025 14:09

Back to list

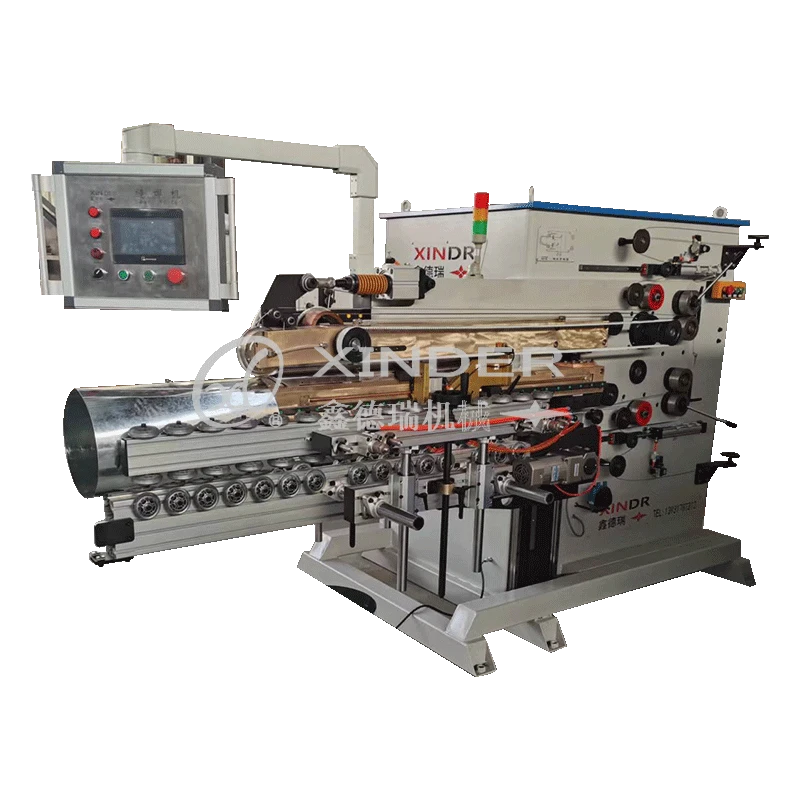

Corrugated Metal Elbow Production Line

When considering the purchase or use of an elbow machine, professionals across various sectors recognize its pivotal role in streamlining manufacturing processes. Boasting a precise focus on bending efficiencies, elbow machines have revolutionized industries from automotive to plumbing, and HVAC systems. Understanding the core attributes, operational benefits, and potential applications of this equipment is essential for any business aiming to enhance productivity and maintain competitive advantage.

Moreover, the trustworthiness of an elbow machine provider is often reflected in customer testimonials and case studies. Businesses seeking to adopt or upgrade their equipment are encouraged to explore detailed analyses of how similar establishments have successfully integrated such machines into their operations. These real-world experiences offer invaluable insights into the practical benefits, such as reduced lead times and lower operational costs, strengthening a buyer’s decision-making process. In terms of applications, elbow machines are remarkably versatile, accommodating a range of industrial requirements. Automotive industries utilize them to craft exhaust pipes, while in plumbing, they are vital for producing various pipe fittings that meet precise angle requirements. For HVAC systems, they aid in constructing components that ensure efficient airflow, all while meeting stringent regulatory standards. This multiplicity of applications highlights the equipment's adaptability, making it a worthwhile investment for diverse manufacturing landscapes. In conclusion, the strategic inclusion of elbow machines in production lines not only optimizes manufacturing efficiency but also aligns with industry best practices, enhancing a company’s competitive edge. As businesses increasingly seek specialized equipment to meet growing demands, understanding the nuances of elbow machine capabilities becomes imperative. Through expertise, proven authority, and a track record of trustworthiness, manufacturers and operators can together push the boundaries of what is achievable, ensuring sustained growth and innovation in their respective fields.

Moreover, the trustworthiness of an elbow machine provider is often reflected in customer testimonials and case studies. Businesses seeking to adopt or upgrade their equipment are encouraged to explore detailed analyses of how similar establishments have successfully integrated such machines into their operations. These real-world experiences offer invaluable insights into the practical benefits, such as reduced lead times and lower operational costs, strengthening a buyer’s decision-making process. In terms of applications, elbow machines are remarkably versatile, accommodating a range of industrial requirements. Automotive industries utilize them to craft exhaust pipes, while in plumbing, they are vital for producing various pipe fittings that meet precise angle requirements. For HVAC systems, they aid in constructing components that ensure efficient airflow, all while meeting stringent regulatory standards. This multiplicity of applications highlights the equipment's adaptability, making it a worthwhile investment for diverse manufacturing landscapes. In conclusion, the strategic inclusion of elbow machines in production lines not only optimizes manufacturing efficiency but also aligns with industry best practices, enhancing a company’s competitive edge. As businesses increasingly seek specialized equipment to meet growing demands, understanding the nuances of elbow machine capabilities becomes imperative. Through expertise, proven authority, and a track record of trustworthiness, manufacturers and operators can together push the boundaries of what is achievable, ensuring sustained growth and innovation in their respective fields.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024