-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Ots . 20, 2025 05:57

Back to list

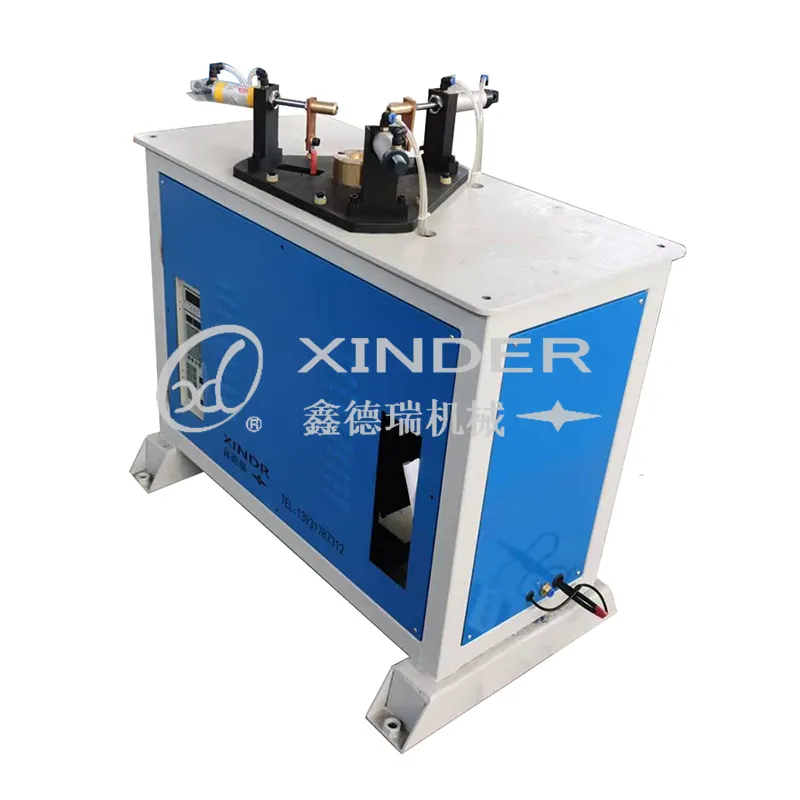

laser soldering machine

In today's ever-evolving manufacturing landscape, the precision and efficiency of machinery play a critical role in maintaining competitive edge. Among these pivotal machines, the round tube necking machine has emerged as an essential tool for industries that demand high-quality tube forming. Designed to reduce the diameter of tubes without compromising their structural integrity, these machines are at the heart of numerous applications ranging from automotive and aerospace to construction and HVAC systems.

Round tube necking machines are leveraged by industries that prioritize both customization and scalability. For instance, the automotive industry relies on precise tubular components to guarantee vehicle safety and efficiency. These machines allow manufacturers to produce custom-sized components that meet stringent regulatory standards without the exorbitant costs associated with specialized tooling. Similarly, the aerospace sector, which demands unwavering reliability, utilizes these machines to fabricate components that contribute to the overall performance and safety of aircraft structures. In terms of authoritativeness, leading manufacturers of round tube necking machines are continuously pushing the boundaries of innovation. They invest in research and development to introduce enhancements that improve efficiency, reduce energy consumption, and support sustainable manufacturing practices. Companies that produce these machines are often at the forefront of technological advancement, setting benchmarks in machine accuracy, control precision, and operational safety. For businesses considering the acquisition of a round tube necking machine, trustworthiness in the supplier is crucial. Reputable suppliers provide comprehensive service packages that encompass installation, training, and after-sales support. This commitment to customer success ensures that businesses can maximize the potential of their investment. Moreover, a trustworthy supplier often offers warranties and guarantees that protect the purchaser from unforeseen operational issues, underscoring their confidence in the machine’s durability and performance. In conclusion, the role of round tube necking machines in modern manufacturing cannot be overstated. Their ability to deliver precision-formed tubular components economically and efficiently makes them a valuable asset in any production line. As technologies evolve, so too will the capabilities of these machines, offering users the potential to explore new horizons in product design and application. For companies poised to invest in this technology, aligning with experienced operators and reputable suppliers will ensure that the integration of a round tube necking machine into their operations is both seamless and rewarding. As industries continue to demand custom solutions, these machines stand as testaments to the synergy between innovative design and industrial application, fulfilling a critical niche in the fabrication of components that drive the future of manufacturing.

Round tube necking machines are leveraged by industries that prioritize both customization and scalability. For instance, the automotive industry relies on precise tubular components to guarantee vehicle safety and efficiency. These machines allow manufacturers to produce custom-sized components that meet stringent regulatory standards without the exorbitant costs associated with specialized tooling. Similarly, the aerospace sector, which demands unwavering reliability, utilizes these machines to fabricate components that contribute to the overall performance and safety of aircraft structures. In terms of authoritativeness, leading manufacturers of round tube necking machines are continuously pushing the boundaries of innovation. They invest in research and development to introduce enhancements that improve efficiency, reduce energy consumption, and support sustainable manufacturing practices. Companies that produce these machines are often at the forefront of technological advancement, setting benchmarks in machine accuracy, control precision, and operational safety. For businesses considering the acquisition of a round tube necking machine, trustworthiness in the supplier is crucial. Reputable suppliers provide comprehensive service packages that encompass installation, training, and after-sales support. This commitment to customer success ensures that businesses can maximize the potential of their investment. Moreover, a trustworthy supplier often offers warranties and guarantees that protect the purchaser from unforeseen operational issues, underscoring their confidence in the machine’s durability and performance. In conclusion, the role of round tube necking machines in modern manufacturing cannot be overstated. Their ability to deliver precision-formed tubular components economically and efficiently makes them a valuable asset in any production line. As technologies evolve, so too will the capabilities of these machines, offering users the potential to explore new horizons in product design and application. For companies poised to invest in this technology, aligning with experienced operators and reputable suppliers will ensure that the integration of a round tube necking machine into their operations is both seamless and rewarding. As industries continue to demand custom solutions, these machines stand as testaments to the synergy between innovative design and industrial application, fulfilling a critical niche in the fabrication of components that drive the future of manufacturing.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024