-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

The Importance of Customization in Steel Barrel Making Machines: Meeting Diverse Industrial Needs

Steel barrels, or steel drums, are essential containers used across various industries for packaging, storing, and transporting materials like chemicals, oil, food, and pharmaceuticals. Given the diverse nature of the products these barrels contain, the steel barrel manufacturing process must be flexible to meet specific industrial requirements. Customization in steel barrel making machines plays a crucial role in enabling manufacturers to produce barrels that cater to the varying demands of different industries. This essay explores the importance of customization in steel barrel making machines and how it helps meet the specific needs of a wide range of industries.

Steel Barrel Making Machines: Adapting to Different Barrel Sizes and Capacities

One of the most significant ways in which customization in steel barrel making machines impacts the manufacturing process is through the ability to produce barrels in varying sizes and capacities. Not all industries require standard-sized barrels, and many sectors require containers that meet specific volume needs. For example, the chemical industry may need barrels capable of holding large quantities of hazardous materials, while the food and beverage industry might require smaller barrels for more specialized applications.

Customizable machines allow for adjustable roller configurations and automated feeding systems that can accommodate different sizes of steel sheets. These machines can easily switch between producing 55-gallon drums and smaller 10- or 20-gallon barrels, ensuring that production is tailored to customer demands. The adjustable dies in certain machines allow operators to change the diameter and height of the barrel without the need for extensive retooling, making it easier to respond quickly to market changes or special orders.

Customization of Steel Barrel Making Machines for Material Type and Coating

Different industries often require steel barrels that are compatible with specific types of materials, such as food-grade containers or drums designed to hold corrosive chemicals. Barrel production line can be customized to handle a variety of materials, including cold-rolled steel, galvanized steel, or stainless steel. Each material has different properties and requirements for handling, and customized machines ensure that the barrels meet the necessary standards for strength, durability, and safety.

Steel Barrel Making Machines: Meeting Specific Industry Standards and Regulatory Requirements

Another key aspect of customization in steel barrel making machine is their ability to meet industry-specific standards and regulatory requirements. Different industries are subject to various safety, quality, and environmental regulations. For example, in the pharmaceutical industry, barrels must comply with stringent standards for cleanliness, non-reactivity, and safety. Similarly, in industries that handle hazardous materials, barrels need to meet specific requirements related to leak prevention, pressure resistance, and labeling.

Steel barrel making machines can be customized to accommodate these regulatory needs by incorporating features such as pressure testing systems, leak detection systems, and automated labeling systems. Pressure testing machines, for example, can ensure that barrels are capable of withstanding the internal pressure exerted by liquids or gases without failing. Similarly, automated systems can ensure that all barrels are properly labeled with compliance marks, batch numbers, or safety warnings, reducing human error and improving overall accuracy.

Customization also allows manufacturers to adjust the machines to create barrels that meet environmental standards, such as those designed for recycling or compliance with sustainability guidelines. For example, eco-friendly coatings or recyclable materials can be incorporated into the manufacturing process to ensure that the barrels meet the latest environmental regulations.

Customization in barrel making machine is essential for meeting the diverse and ever-evolving needs of industries that rely on these durable containers. Whether it’s adjusting for different barrel sizes, material types, coatings, regulatory compliance, or production efficiency, customized machines enable manufacturers to deliver high-quality barrels that meet the unique requirements of their clients. By offering flexibility, precision, and adaptability, these machines help manufacturers stay competitive, meet industry standards, and cater to the growing demand for specialized packaging solutions. As industries continue to diversify and innovate, the role of customizable steel barrel making machines will only become more critical in ensuring that packaging remains safe, efficient, and tailored to specific needs.

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

-

Revolutionizing Packaging: The Role of Welding Machines in Steel and Tin Can ManufacturingNewsJul.18,2025

-

Precision in Motion: Exploring Seam Welding Machines for Industrial FabricationNewsJul.18,2025

-

Mastering Precision Bending: A Guide to Tube Benders and Their TypesNewsJul.18,2025

-

Inside the World of Barrel Manufacturing: Machines, Lines, and CostsNewsJul.18,2025

-

Exploring the Technology Behind Elbow Bending Machines in Pipe ManufacturingNewsJul.18,2025

-

Unlocking the Power of Light: Exploring Modern Laser Welding SolutionsNewsJul.15,2025

-

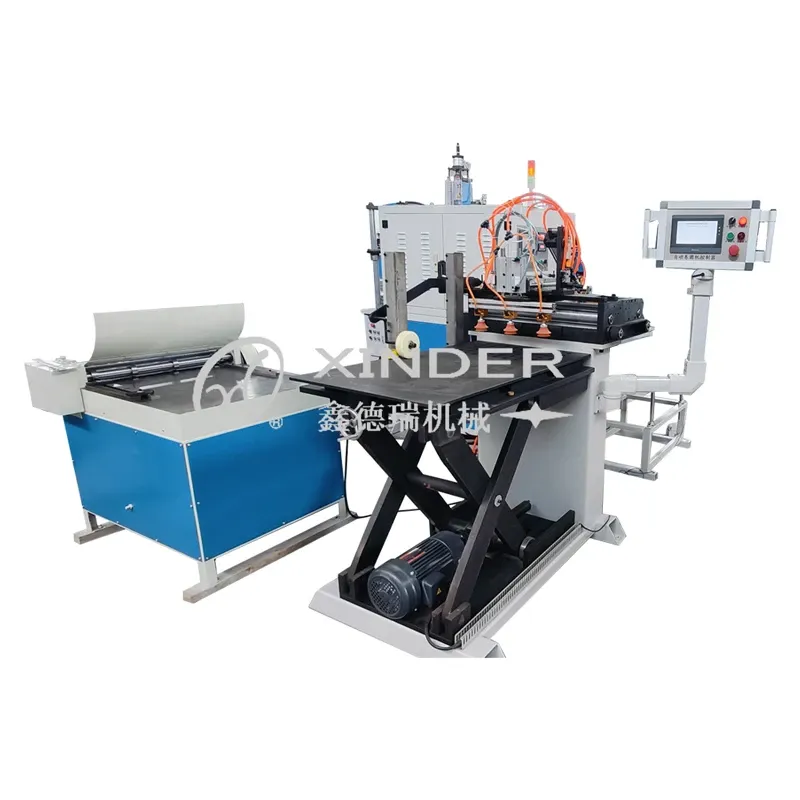

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024