-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Led . 21, 2025 05:00

Back to list

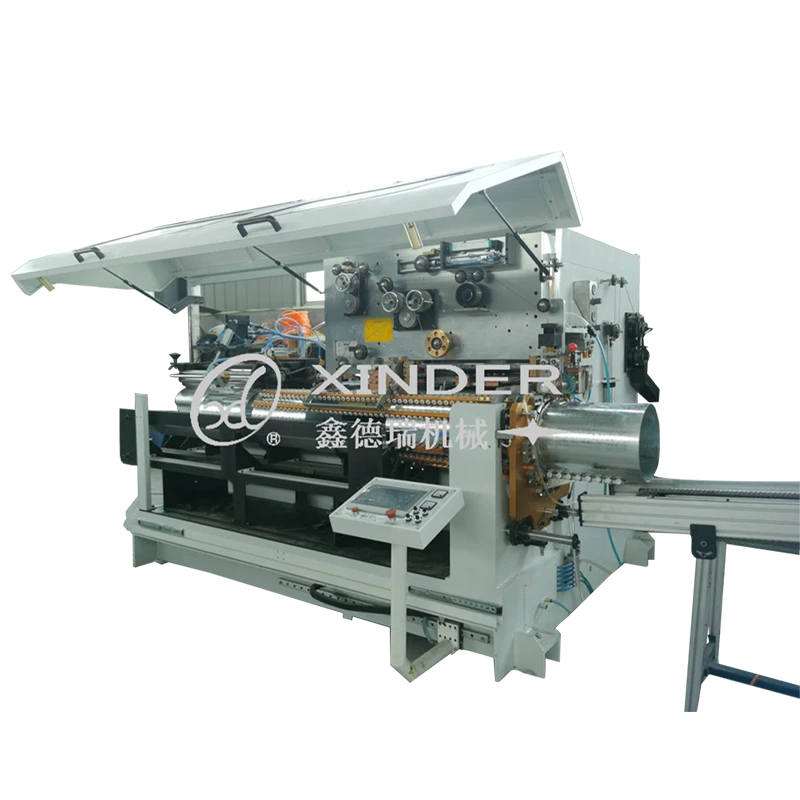

Steel Drum Seam Welding Machine

The evolution of welding technology has taken a quantum leap with the advent of the automatic orbital welding machine. This cutting-edge equipment has revolutionized industries by enhancing precision, efficiency, and overall weld quality, making it an indispensable asset for any production line that prioritizes meticulous craftsmanship and operational efficiency.

Authoritativeness is underscored by the machine's proven track record in high-stakes environments. For instance, in the semiconductor industry, where particle contamination can compromise an entire batch of products, automatic orbital welding machine's precision ensures clean, smooth joints that adhere to the highest cleanliness standards. Furthermore, its adoption across various global industries speaks volumes about its reliability and effectiveness. Trustworthiness is further solidified by the continuous improvements and innovations in the design and functionality of these machines. Leading manufacturers are investing heavily in research and development to enhance these systems, making them even more user-friendly and adaptable to various industrial needs. Features such as user-friendly interfaces, programmable control units, and remote diagnostics enable operators to maintain high levels of productivity while ensuring ease of integration into existing workflows. Customers who have transitioned to automatic orbital welding machines often report a substantial improvement in production throughput and a notable decrease in operational hiccups. This transition not only boosts the operational capacity but also allows skilled welders to focus on more complex tasks that require human ingenuity. The synergy between man and machine in these scenarios demonstrates the compelling power of automation in modern manufacturing. In conclusion, the automatic orbital welding machine represents a fusion of experience, expertise, authoritativeness, and trustworthiness, making it an investment that pays dividends through improved quality, efficiency, and reliability. As industries continue to evolve and demands for precision grow, embracing such technological advancements is not merely an option but a necessity for companies poised to stay ahead in today’s competitive landscape. This machine is not just a tool; it is a pivotal component in the pursuit of excellence in industrial manufacturing.

Authoritativeness is underscored by the machine's proven track record in high-stakes environments. For instance, in the semiconductor industry, where particle contamination can compromise an entire batch of products, automatic orbital welding machine's precision ensures clean, smooth joints that adhere to the highest cleanliness standards. Furthermore, its adoption across various global industries speaks volumes about its reliability and effectiveness. Trustworthiness is further solidified by the continuous improvements and innovations in the design and functionality of these machines. Leading manufacturers are investing heavily in research and development to enhance these systems, making them even more user-friendly and adaptable to various industrial needs. Features such as user-friendly interfaces, programmable control units, and remote diagnostics enable operators to maintain high levels of productivity while ensuring ease of integration into existing workflows. Customers who have transitioned to automatic orbital welding machines often report a substantial improvement in production throughput and a notable decrease in operational hiccups. This transition not only boosts the operational capacity but also allows skilled welders to focus on more complex tasks that require human ingenuity. The synergy between man and machine in these scenarios demonstrates the compelling power of automation in modern manufacturing. In conclusion, the automatic orbital welding machine represents a fusion of experience, expertise, authoritativeness, and trustworthiness, making it an investment that pays dividends through improved quality, efficiency, and reliability. As industries continue to evolve and demands for precision grow, embracing such technological advancements is not merely an option but a necessity for companies poised to stay ahead in today’s competitive landscape. This machine is not just a tool; it is a pivotal component in the pursuit of excellence in industrial manufacturing.

Latest News

-

The Rise of Laser Welding in Global Manufacturing: Spotlight on China’s Competitive EdgeNewsJun.05,2025

-

The Power of Precision: Exploring the Role of Automatic Seam Welding Machines in Modern ManufacturingNewsJun.05,2025

-

The Essential Guide to Can Welding Machines: Revolutionizing the Packaging IndustryNewsJun.05,2025

-

Resistance Welding Equipment: A Smart Investment for Industrial ManufacturingNewsJun.05,2025

-

Precision Welding for Modern Manufacturing: The Rise of Automatic Seam Welding MachinesNewsJun.05,2025

-

Laser Welding for Stainless Steel: The Precision Edge in Modern Metal FabricationNewsJun.05,2025

-

The Modern Evolution of Barrel Production: Technology, Machines, and Market PricingNewsMay.22,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024