-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Peb . 15, 2025 23:15

Back to list

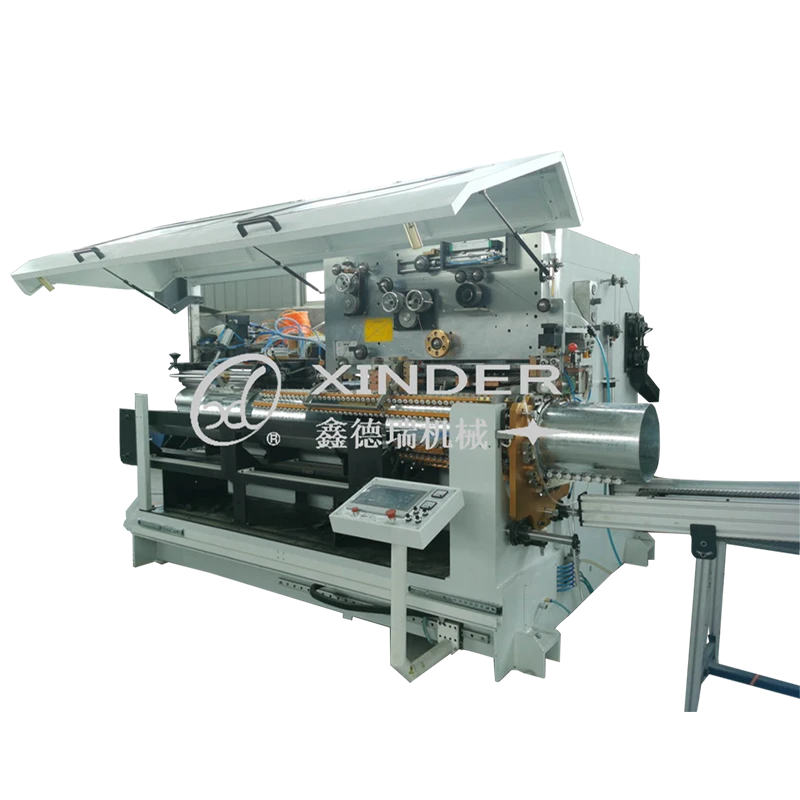

pipeline welder machine

Investing in a quality poly pipe welder is paramount for anyone in the business of pipeline construction, repair, or maintenance. The market offers a plethora of options, but understanding which welder best suits your needs requires more than just a casual glance. It demands an in-depth analysis of the different types of poly pipe welders, their features, and what makes them stand out.

When considering the purchase of a poly pipe welder, paying attention to additional features can also make a significant difference. For instance, whether a machine includes an automatic heating plate retraction system or support for remote control operations can affect usability, especially for large-scale or long-duration projects. Moreover, machines that support a comprehensive range of pipe diameters offer greater flexibility and reduce the need to acquire multiple welding devices for different project needs. Purchasing a poly pipe welder isn't just about selecting the right type; it also involves finding a trusted supplier who provides well-built, reliable equipment alongside excellent after-sales support. Buyers should research brands that are known for their durability and have a track record of innovation, ensuring that their products meet the latest safety and functionality standards. Likewise, having access to thorough user documentation and technical support can significantly increase the prospects of seamless welding operations. Ultimately, the decision to buy a poly pipe welder should be made with a clear understanding of the specific requirements of your projects and the environments in which they'll operate. Keeping abreast of technological advancements and tapping into expert reviews and user testimonials can provide invaluable insights, ensuring you invest in a machine that not only meets but exceeds your operational expectations.

When considering the purchase of a poly pipe welder, paying attention to additional features can also make a significant difference. For instance, whether a machine includes an automatic heating plate retraction system or support for remote control operations can affect usability, especially for large-scale or long-duration projects. Moreover, machines that support a comprehensive range of pipe diameters offer greater flexibility and reduce the need to acquire multiple welding devices for different project needs. Purchasing a poly pipe welder isn't just about selecting the right type; it also involves finding a trusted supplier who provides well-built, reliable equipment alongside excellent after-sales support. Buyers should research brands that are known for their durability and have a track record of innovation, ensuring that their products meet the latest safety and functionality standards. Likewise, having access to thorough user documentation and technical support can significantly increase the prospects of seamless welding operations. Ultimately, the decision to buy a poly pipe welder should be made with a clear understanding of the specific requirements of your projects and the environments in which they'll operate. Keeping abreast of technological advancements and tapping into expert reviews and user testimonials can provide invaluable insights, ensuring you invest in a machine that not only meets but exceeds your operational expectations.

Prev:

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024