-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Peb . 13, 2025 16:18

Back to list

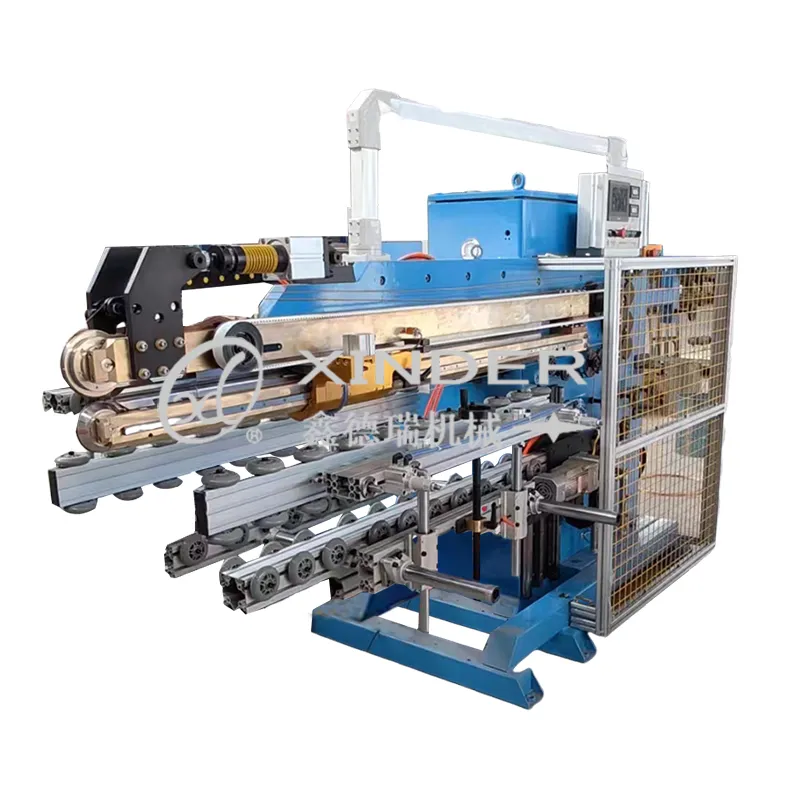

metal bending machine for sale

In the vast landscape of industrial machinery, the flat metal bending machine has cemented its place as an essential tool for countless sectors. With its precise engineering and robust capabilities, this machine offers unparalleled benefits to those needing accurate metal manipulation. In this article, we delve deep into the expertise-driven utility, authority of application, and the trustworthy nature of flat metal bending machines from an expert standpoint in the industry.

Authority in the crafting of flat metal bending machines is derived not just from their technological prowess but also from their build quality. Top manufacturers employ premium-grade materials like hardened steel and high-tensile alloys to construct machines that can withstand years of heavy use without compromising on accuracy. The recognition of brands synonymous with excellence, such as Amada or Trumpf, further instills confidence in buyers and users alike. These industry leaders continually conduct research and innovate, pushing boundaries to enhance machine efficiency and incorporating eco-friendly practices, aligning with global sustainability goals. Trustworthiness of these machines hinges on their proven track record in varied industrial applications. From automotive to shipbuilding, flat metal bending machines serve as linchpins in production lines. Their reliability has been well-documented in case studies that highlight significant time and cost savings afforded to corporations embracing this technology. Moreover, manufacturers often provide extensive training and support, ensuring operators are fully versed in maximizing the machine's potential while adhering to safety standards. In conclusion, the flat metal bending machine is more than just an apparatus for shaping metal. It's a testament to the evolution of industrial machinery, embodying precision, power, and durability. Its rising adoption across sectors is a direct reflection of its unmatched capability to improve operational efficiencies and product quality. For anyone in the market for a bending solution, it is crucial to select a machine that offers the right balance between technology and tactile expertise. Not only will this ensure a robust return on investment, but also a sustained competitive edge in the ever-evolving landscape of metal fabrication.

Authority in the crafting of flat metal bending machines is derived not just from their technological prowess but also from their build quality. Top manufacturers employ premium-grade materials like hardened steel and high-tensile alloys to construct machines that can withstand years of heavy use without compromising on accuracy. The recognition of brands synonymous with excellence, such as Amada or Trumpf, further instills confidence in buyers and users alike. These industry leaders continually conduct research and innovate, pushing boundaries to enhance machine efficiency and incorporating eco-friendly practices, aligning with global sustainability goals. Trustworthiness of these machines hinges on their proven track record in varied industrial applications. From automotive to shipbuilding, flat metal bending machines serve as linchpins in production lines. Their reliability has been well-documented in case studies that highlight significant time and cost savings afforded to corporations embracing this technology. Moreover, manufacturers often provide extensive training and support, ensuring operators are fully versed in maximizing the machine's potential while adhering to safety standards. In conclusion, the flat metal bending machine is more than just an apparatus for shaping metal. It's a testament to the evolution of industrial machinery, embodying precision, power, and durability. Its rising adoption across sectors is a direct reflection of its unmatched capability to improve operational efficiencies and product quality. For anyone in the market for a bending solution, it is crucial to select a machine that offers the right balance between technology and tactile expertise. Not only will this ensure a robust return on investment, but also a sustained competitive edge in the ever-evolving landscape of metal fabrication.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024