-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

gen. . 21, 2025 04:14

Back to list

1.20-30 liter steel drum fully automatic welding machine

Automatic girth welders have revolutionized the welding industry by providing an efficient, precise, and reliable solution for welding large cylindrical structures. These machines are specifically designed to enhance productivity, reduce human error, and deliver consistent quality in welding operations, all of which are crucial in industries such as shipbuilding, storage tank construction, and pipeline assembly.

Trustworthiness in automatic girth welders is further cemented by advancements in safety features. Modern units are equipped with sensors and automated systems that monitor the welding process, ensuring safe operation and providing alerts in case of anomalies. These features not only protect human operators but also safeguard the equipment, preventing unnecessary downtime due to malfunctions or accidents. Selecting the right automatic girth welder involves assessing the specific needs of your project. It's crucial to consider factors such as the size of the structures being welded, the types of materials involved, and the environmental conditions under which the welder will operate. Consulting with manufacturers or specialists who have extensive knowledge of automatic girth welders can provide valuable insights and recommendations tailored to your specific applications. Finally, integrating automatic girth welders into your operations can reflect positively on your company's commitment to innovation and quality. By adopting these advanced welding solutions, businesses not only enhance their efficiency and output but also position themselves as industry leaders who are embracing technology to deliver superior results. In conclusion, automatic girth welders have become indispensable tools in the realm of industrial welding. Their ability to deliver quick, precise, and reliable welds makes them an essential asset for any organization looking to optimize its welding operations. Through professional expertise, a focus on precision, and a commitment to safety and reliability, automatic girth welders contribute significantly to the overall success and competency of any welding project.

Trustworthiness in automatic girth welders is further cemented by advancements in safety features. Modern units are equipped with sensors and automated systems that monitor the welding process, ensuring safe operation and providing alerts in case of anomalies. These features not only protect human operators but also safeguard the equipment, preventing unnecessary downtime due to malfunctions or accidents. Selecting the right automatic girth welder involves assessing the specific needs of your project. It's crucial to consider factors such as the size of the structures being welded, the types of materials involved, and the environmental conditions under which the welder will operate. Consulting with manufacturers or specialists who have extensive knowledge of automatic girth welders can provide valuable insights and recommendations tailored to your specific applications. Finally, integrating automatic girth welders into your operations can reflect positively on your company's commitment to innovation and quality. By adopting these advanced welding solutions, businesses not only enhance their efficiency and output but also position themselves as industry leaders who are embracing technology to deliver superior results. In conclusion, automatic girth welders have become indispensable tools in the realm of industrial welding. Their ability to deliver quick, precise, and reliable welds makes them an essential asset for any organization looking to optimize its welding operations. Through professional expertise, a focus on precision, and a commitment to safety and reliability, automatic girth welders contribute significantly to the overall success and competency of any welding project.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

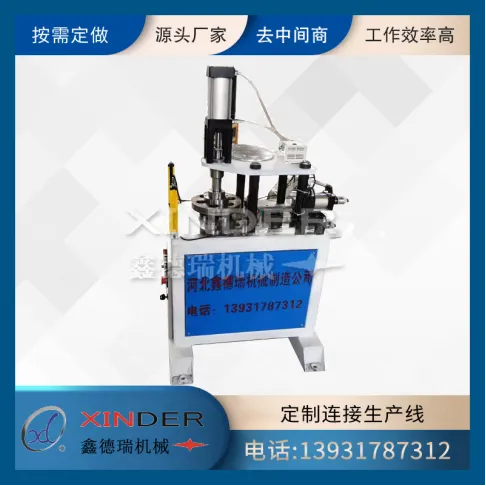

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024