-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

feb . 06, 2025 05:21

Back to list

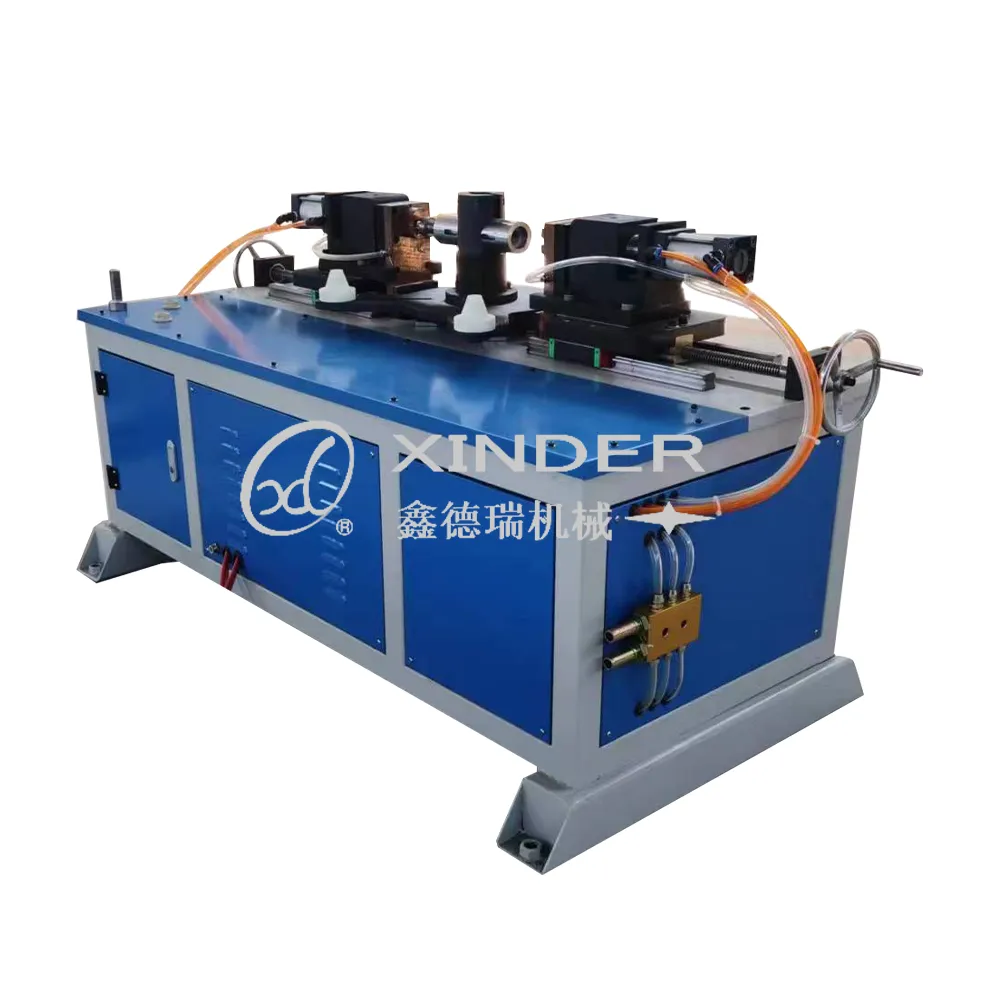

Fully Automatic Pipe Cutting Machine

The dynamic landscape of modern manufacturing is driven by the pursuit of precision, efficiency, and innovation. In this context, automatic tube cutting machines have emerged as indispensable tools, revolutionizing the way industries approach metal fabrication. With the relentless demand for accuracy and speed in production processes, these machines stand at the forefront, offering unparalleled reliability and performance.

In addition to technological sophistication, the real-world experience of utilizing automatic tube cutting machines solidifies their standing in the manufacturing sector. Companies that have integrated these machines into their production lines often report substantial improvements in operational efficiency and product quality. They highlight the machines’ user-friendly interfaces, which allow operators to easily program complex jobs, adapting swiftly to new production demands without extensive retooling. Safety, another critical concern in manufacturing, is also addressed robustly by automatic tube cutting machines. They are equipped with advanced safety features, such as emergency stop functions and protective enclosures, significantly reducing workplace accidents. This focus on safety not only protects operators but also means that companies can maintain a stable workforce, unencumbered by frequent injuries or disruptions. To remain competitive in an ever-demanding market, investing in automatic tube cutting machines is not just an option but a strategic imperative. Their ability to enhance production capabilities while ensuring safety, precision, and cost-effectiveness positions them as a key asset in any forward-thinking manufacturing enterprise. Choosing the right automatic tube cutting machine requires careful consideration of a company's specific needs and production goals. Consulting with experts in the field can provide insights into the most suitable models and configurations, tailored to deliver optimal performance. Furthermore, commitment to regular maintenance and training ensures these investments continue to deliver long-term benefits. In conclusion, the impact of automatic tube cutting machines on manufacturing efficiency, precision, and sustainability cannot be overstated. As industries worldwide recognize their transformative potential, these machines continue to drive innovation, setting new benchmarks in cutting technology. Companies that embrace this evolution are well-positioned to lead in their respective sectors, reaping the rewards of enhanced productivity and competitiveness.

In addition to technological sophistication, the real-world experience of utilizing automatic tube cutting machines solidifies their standing in the manufacturing sector. Companies that have integrated these machines into their production lines often report substantial improvements in operational efficiency and product quality. They highlight the machines’ user-friendly interfaces, which allow operators to easily program complex jobs, adapting swiftly to new production demands without extensive retooling. Safety, another critical concern in manufacturing, is also addressed robustly by automatic tube cutting machines. They are equipped with advanced safety features, such as emergency stop functions and protective enclosures, significantly reducing workplace accidents. This focus on safety not only protects operators but also means that companies can maintain a stable workforce, unencumbered by frequent injuries or disruptions. To remain competitive in an ever-demanding market, investing in automatic tube cutting machines is not just an option but a strategic imperative. Their ability to enhance production capabilities while ensuring safety, precision, and cost-effectiveness positions them as a key asset in any forward-thinking manufacturing enterprise. Choosing the right automatic tube cutting machine requires careful consideration of a company's specific needs and production goals. Consulting with experts in the field can provide insights into the most suitable models and configurations, tailored to deliver optimal performance. Furthermore, commitment to regular maintenance and training ensures these investments continue to deliver long-term benefits. In conclusion, the impact of automatic tube cutting machines on manufacturing efficiency, precision, and sustainability cannot be overstated. As industries worldwide recognize their transformative potential, these machines continue to drive innovation, setting new benchmarks in cutting technology. Companies that embrace this evolution are well-positioned to lead in their respective sectors, reaping the rewards of enhanced productivity and competitiveness.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024