-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ফেব্রু. . 14, 2025 12:52

Back to list

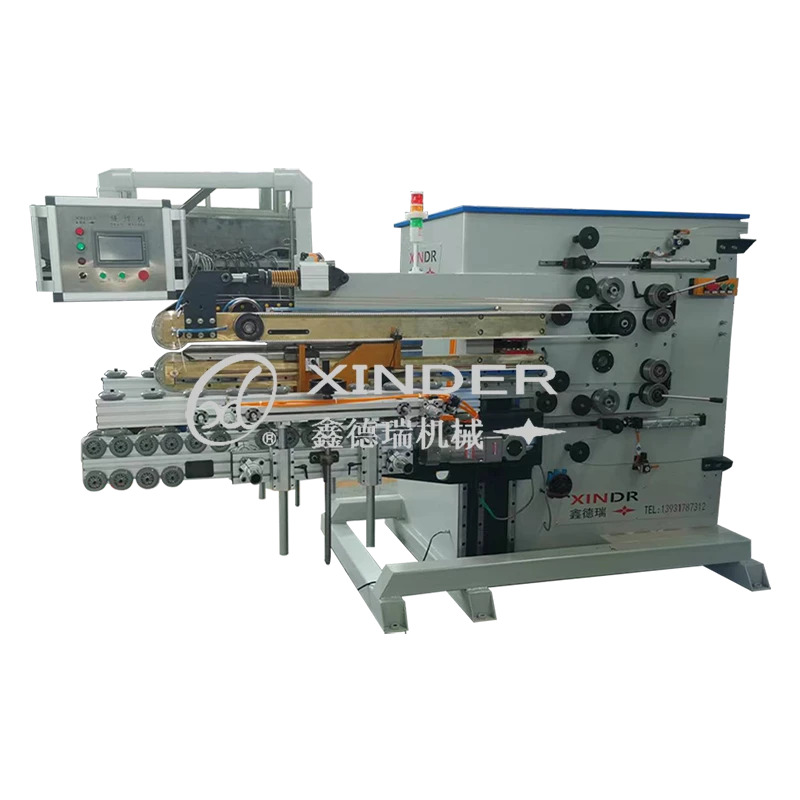

plate bending machine

Exploring the dynamics of plate bending machines reveals an intricate world where precision engineering meets robust material shaping. These machines, pivotal in metal fabrication, are engineered for transforming flat metal plates into curved, angular, or otherwise intricately designed structures. This transformation process is crucial in numerous industries, including automotive manufacturing, aerospace, shipbuilding, and construction.

In the realm of plate bending, expertise is encapsulated not just in the knowledge of machinery, but in the meticulous fine-tuning of each process step. A higher level of skill is required to adjust variables such as pressure level, bending speed, and roll positioning—a task that combines technical know-how with years of hands-on experience. An authoritative source in the plate bending sphere is highlighted not only by quality machine outputs but also by a commitment to innovation and safety. Manufacturers integrate cutting-edge technologies such as CNC controls, which significantly enhance the precision and repeatability of complex bending tasks. This shift towards automation brings about a massive increase in the speed and consistency of production, benefiting industries that demand large-scale fabrication without compromising quality or safety. Trust in plate bending machines is built through rigorous testing and adherence to international industrial standards. Machines that meet or exceed these standards ensure end-products that possess both longevity and reliability, crucial for structures exposed to extreme conditions or extensive use. Consistent maintenance regimes and proper operator training further augment the dependability of these machines, reducing downtime and extending operational life. In conclusion, the full understanding and utilization of plate bending machines require a harmonious blend of experience, technical precision, authoritative innovation, and unwavering trust. For businesses aiming to stay competitive, investing in advanced machines, backed by training and maintenance, is key. As industries evolve, the role of plate bending machines will undoubtedly continue to expand, paving the way for more complex and ambitious engineering projects.

In the realm of plate bending, expertise is encapsulated not just in the knowledge of machinery, but in the meticulous fine-tuning of each process step. A higher level of skill is required to adjust variables such as pressure level, bending speed, and roll positioning—a task that combines technical know-how with years of hands-on experience. An authoritative source in the plate bending sphere is highlighted not only by quality machine outputs but also by a commitment to innovation and safety. Manufacturers integrate cutting-edge technologies such as CNC controls, which significantly enhance the precision and repeatability of complex bending tasks. This shift towards automation brings about a massive increase in the speed and consistency of production, benefiting industries that demand large-scale fabrication without compromising quality or safety. Trust in plate bending machines is built through rigorous testing and adherence to international industrial standards. Machines that meet or exceed these standards ensure end-products that possess both longevity and reliability, crucial for structures exposed to extreme conditions or extensive use. Consistent maintenance regimes and proper operator training further augment the dependability of these machines, reducing downtime and extending operational life. In conclusion, the full understanding and utilization of plate bending machines require a harmonious blend of experience, technical precision, authoritative innovation, and unwavering trust. For businesses aiming to stay competitive, investing in advanced machines, backed by training and maintenance, is key. As industries evolve, the role of plate bending machines will undoubtedly continue to expand, paving the way for more complex and ambitious engineering projects.

Latest News

-

The Rise of Laser Welding in Global Manufacturing: Spotlight on China’s Competitive EdgeNewsJun.05,2025

-

The Power of Precision: Exploring the Role of Automatic Seam Welding Machines in Modern ManufacturingNewsJun.05,2025

-

The Essential Guide to Can Welding Machines: Revolutionizing the Packaging IndustryNewsJun.05,2025

-

Resistance Welding Equipment: A Smart Investment for Industrial ManufacturingNewsJun.05,2025

-

Precision Welding for Modern Manufacturing: The Rise of Automatic Seam Welding MachinesNewsJun.05,2025

-

Laser Welding for Stainless Steel: The Precision Edge in Modern Metal FabricationNewsJun.05,2025

-

The Modern Evolution of Barrel Production: Technology, Machines, and Market PricingNewsMay.22,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024