-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ফেব্রু. . 19, 2025 08:14

Back to list

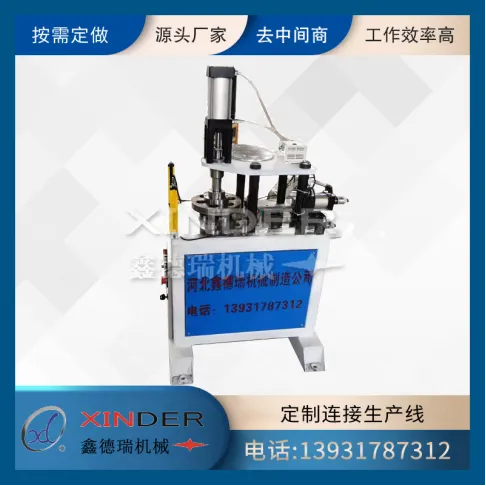

metal bending machine for sale

Selecting the right metal coating bucket equipment is crucial for ensuring optimal performance, longevity, and efficiency in industrial processes. This specialized equipment plays a pivotal role in industries ranging from automotive to construction, contributing to both product aesthetics and durability. Here are some key insights into the latest innovations, expert recommendations, and reliable practices in the field of metal coating technology.

Authoritativeness in the metal coating equipment sector is often demonstrated by compliance with international standards and certifications. Equipment that meets ISO and other relevant certifications ensures that processes align with global best practices. This not only guarantees product quality but also enhances the credibility of the manufacturing process, which is essential for maintaining trust with clients and stakeholders. To ensure the trustworthiness of metal coating equipment, it's essential to conduct thorough field tests and validation. Manufacturers often provide case studies and performance data that illustrate the reliability and efficiency of their products. Additionally, customer testimonials and third-party reviews offer invaluable insights into the equipment's real-world performance and durability. The purchase and integration of metal coating bucket equipment also require consideration of service and support. Reliable manufacturers offer comprehensive support services, including training, maintenance, and readily available spare parts. The availability of these services ensures that downtime is minimized, and operations remain uninterrupted, thus protecting the investment. Finally, companies need to consider the long-term scalability when selecting their metal coating equipment. As businesses grow, having equipment that can handle increased volume and complexity without significant upgrades is invaluable. Scalable solutions prevent the need for frequent replacements, thereby reducing capital expenditure over time. Investing in state-of-the-art metal coating bucket equipment not only improves operational efficiency and product quality but also positions a company as a leader in modern manufacturing practices. Future innovations are likely to focus on further automation improvements, enhanced environmental considerations, and even more refined material handling capabilities, making the choice of initial equipment even more critical for long-term success.

Authoritativeness in the metal coating equipment sector is often demonstrated by compliance with international standards and certifications. Equipment that meets ISO and other relevant certifications ensures that processes align with global best practices. This not only guarantees product quality but also enhances the credibility of the manufacturing process, which is essential for maintaining trust with clients and stakeholders. To ensure the trustworthiness of metal coating equipment, it's essential to conduct thorough field tests and validation. Manufacturers often provide case studies and performance data that illustrate the reliability and efficiency of their products. Additionally, customer testimonials and third-party reviews offer invaluable insights into the equipment's real-world performance and durability. The purchase and integration of metal coating bucket equipment also require consideration of service and support. Reliable manufacturers offer comprehensive support services, including training, maintenance, and readily available spare parts. The availability of these services ensures that downtime is minimized, and operations remain uninterrupted, thus protecting the investment. Finally, companies need to consider the long-term scalability when selecting their metal coating equipment. As businesses grow, having equipment that can handle increased volume and complexity without significant upgrades is invaluable. Scalable solutions prevent the need for frequent replacements, thereby reducing capital expenditure over time. Investing in state-of-the-art metal coating bucket equipment not only improves operational efficiency and product quality but also positions a company as a leader in modern manufacturing practices. Future innovations are likely to focus on further automation improvements, enhanced environmental considerations, and even more refined material handling capabilities, making the choice of initial equipment even more critical for long-term success.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024