-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ফেব্রু. . 10, 2025 19:17

Back to list

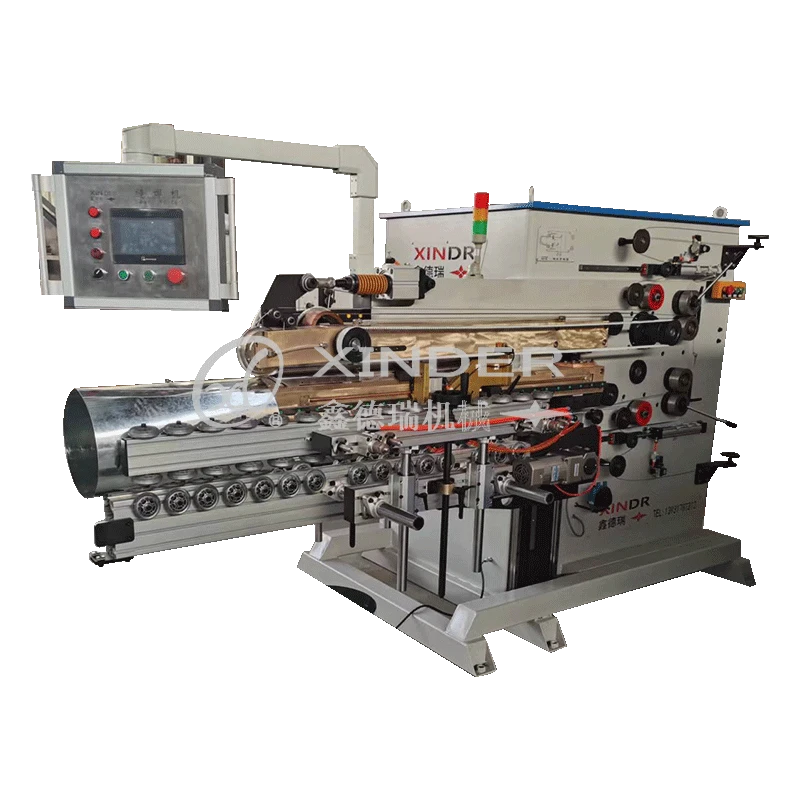

Hydraulic Bending Machine

In the realm of modern manufacturing, the hydraulic sheet metal bending machine stands out as a pivotal tool that enhances both efficiency and precision. Its significance cannot be overstated when it comes to achieving optimal angles and shapes in metal fabrication. However, understanding the intricacies of this machinery requires a deep dive into its functionalities, innovations, and applications, which have transformed it into an indispensable part of the fabrication process.

Innovation in hydraulic bending technology has propelled these machines to new heights. With the integration of computer numerical control (CNC), operators can now program complex bending sequences with precision. This advancement allows for the automation of repetitive tasks, freeing up skilled labor for more intricate operations and increasing overall efficiency. The CNC technology also facilitates faster setup times and enables quick adjustments, which is essential for just-in-time manufacturing processes. From an expertise perspective, operating a hydraulic sheet metal bending machine demands a thorough understanding of both the machinery and the properties of the materials being used. Skilled technicians are required to interpret blueprints, calculate bend deductions, and program CNC systems to execute precision tasks accurately. Ongoing training and hands-on experience are critical to mastering the intricacies of hydraulic bending machines and their applications. Authoritativeness in this domain is established through continuous innovation and adherence to industry standards. Leading manufacturers invest in research and development to advance their machines’ capabilities, ensuring they comply with global safety and environmental regulations. This commitment not only solidifies their position in the market but also enhances the trustworthiness of their offerings. By maintaining a focus on quality and reliability, companies can confidently assure their clients of the machines' long-term performance and durability. In conclusion, the hydraulic sheet metal bending machine embodies a perfect blend of engineering excellence and practical application. Its profound impact on metal fabrication processes is a testament to its robustness, versatility, and precision. As industries continue to evolve and demand higher standards of efficiency and accuracy, these machines will undoubtedly play a critical role in shaping the future of manufacturing. For businesses invested in quality production, adopting advanced hydraulic bending technology is not just an option—it’s a strategic imperative that promises sustained competitive advantage and operational excellence.

Innovation in hydraulic bending technology has propelled these machines to new heights. With the integration of computer numerical control (CNC), operators can now program complex bending sequences with precision. This advancement allows for the automation of repetitive tasks, freeing up skilled labor for more intricate operations and increasing overall efficiency. The CNC technology also facilitates faster setup times and enables quick adjustments, which is essential for just-in-time manufacturing processes. From an expertise perspective, operating a hydraulic sheet metal bending machine demands a thorough understanding of both the machinery and the properties of the materials being used. Skilled technicians are required to interpret blueprints, calculate bend deductions, and program CNC systems to execute precision tasks accurately. Ongoing training and hands-on experience are critical to mastering the intricacies of hydraulic bending machines and their applications. Authoritativeness in this domain is established through continuous innovation and adherence to industry standards. Leading manufacturers invest in research and development to advance their machines’ capabilities, ensuring they comply with global safety and environmental regulations. This commitment not only solidifies their position in the market but also enhances the trustworthiness of their offerings. By maintaining a focus on quality and reliability, companies can confidently assure their clients of the machines' long-term performance and durability. In conclusion, the hydraulic sheet metal bending machine embodies a perfect blend of engineering excellence and practical application. Its profound impact on metal fabrication processes is a testament to its robustness, versatility, and precision. As industries continue to evolve and demand higher standards of efficiency and accuracy, these machines will undoubtedly play a critical role in shaping the future of manufacturing. For businesses invested in quality production, adopting advanced hydraulic bending technology is not just an option—it’s a strategic imperative that promises sustained competitive advantage and operational excellence.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024