-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ফেব্রু. . 10, 2025 22:23

Back to list

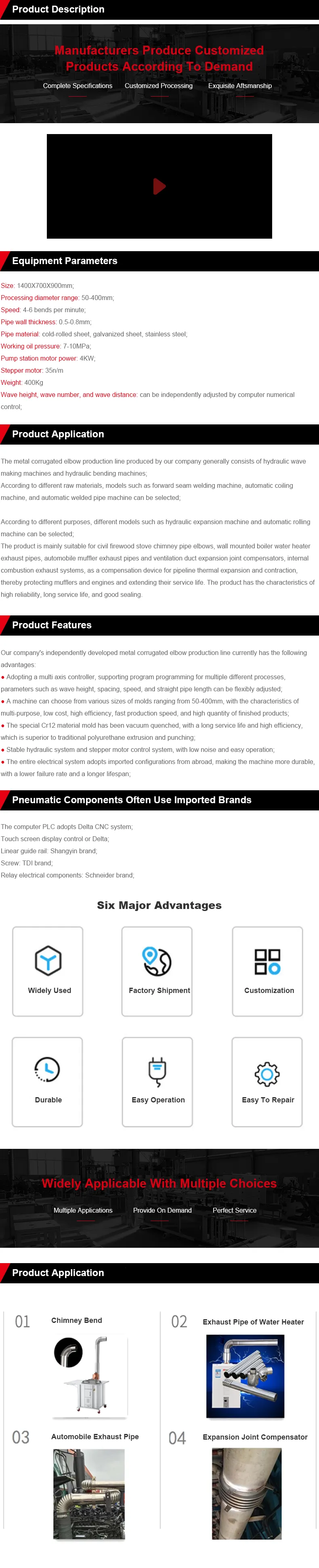

Hydraulic Bending Machine

The CNC hydraulic bending machine has revolutionized modern manufacturing processes by combining precision engineering with advanced hydraulic technology. This equipment is at the core of industries where metal forming is crucial, spanning sectors such as automotive, aerospace, and construction. The integration of computerized numerical control (CNC) into hydraulic bending machines has not only enhanced the operational efficiency but also elevated the precision of metal bending tasks.

The trustworthiness of CNC hydraulic bending machines is a critical factor that influences purchasing decisions. Buyers typically look for evidence of long-term reliability, minimal downtime, and ease of maintenance. By opting for machines from established brands with a proven track record, businesses can operate with confidence, knowing that they are investing in equipment designed for high performance and resilience. Furthermore, comprehensive post-sales support and readily available spare parts build trust and ensure that any issues can be swiftly addressed without disrupting production. In practical terms, using a CNC hydraulic bending machine translates to tangible benefits in efficiency and cost-effectiveness. Manufacturers can achieve higher throughput with fewer errors, directly impacting the bottom line. Additionally, the flexibility of these machines allows for quick changeovers, making it feasible to switch between different production requirements without significant downtime. This versatility is particularly beneficial in environments where customization and rapid prototyping are essential. Ultimately, CNC hydraulic bending machines represent a blend of cutting-edge technology and practical utility. Businesses that harness the potential of these machines can expect to see a marked improvement in productivity and product quality. As the industry continues to evolve, these machines will likely incorporate even more advanced features, driven by ongoing research and innovations in both software and material sciences. Choosing the right CNC hydraulic bending machine involves considering specific business needs, potential future demands, and the technical specifications best suited to meet those needs. Engaging with manufacturers and experts who offer detailed insights and demonstrations can be invaluable in making an informed decision. As technology progresses, staying updated with the latest advancements in CNC hydraulic bending machines ensures that businesses remain competitive in an ever-demanding market.

The trustworthiness of CNC hydraulic bending machines is a critical factor that influences purchasing decisions. Buyers typically look for evidence of long-term reliability, minimal downtime, and ease of maintenance. By opting for machines from established brands with a proven track record, businesses can operate with confidence, knowing that they are investing in equipment designed for high performance and resilience. Furthermore, comprehensive post-sales support and readily available spare parts build trust and ensure that any issues can be swiftly addressed without disrupting production. In practical terms, using a CNC hydraulic bending machine translates to tangible benefits in efficiency and cost-effectiveness. Manufacturers can achieve higher throughput with fewer errors, directly impacting the bottom line. Additionally, the flexibility of these machines allows for quick changeovers, making it feasible to switch between different production requirements without significant downtime. This versatility is particularly beneficial in environments where customization and rapid prototyping are essential. Ultimately, CNC hydraulic bending machines represent a blend of cutting-edge technology and practical utility. Businesses that harness the potential of these machines can expect to see a marked improvement in productivity and product quality. As the industry continues to evolve, these machines will likely incorporate even more advanced features, driven by ongoing research and innovations in both software and material sciences. Choosing the right CNC hydraulic bending machine involves considering specific business needs, potential future demands, and the technical specifications best suited to meet those needs. Engaging with manufacturers and experts who offer detailed insights and demonstrations can be invaluable in making an informed decision. As technology progresses, staying updated with the latest advancements in CNC hydraulic bending machines ensures that businesses remain competitive in an ever-demanding market.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024