-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ян. . 23, 2025 01:24

Back to list

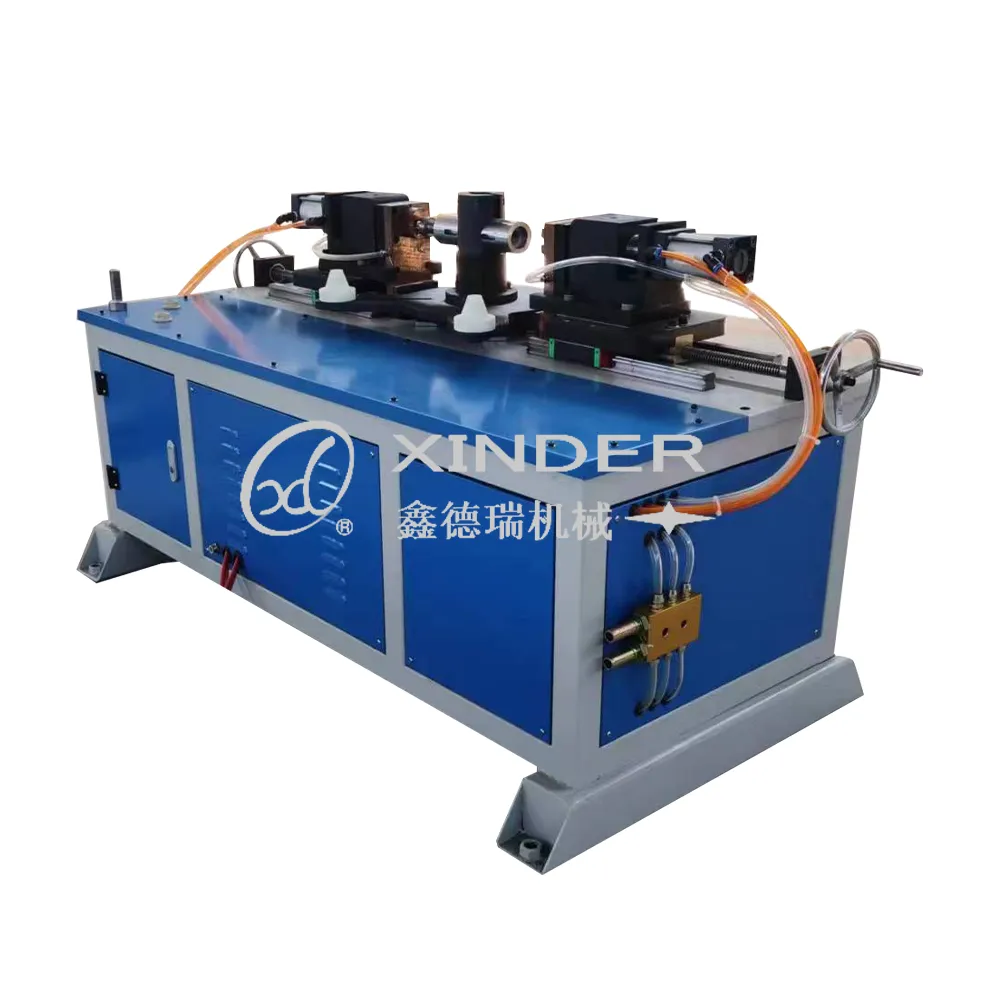

stainless steel automatic welding machine

The evolution of industrial technology has continuously pushed forward the boundaries of manufacturing, creating innovative solutions for age-old challenges. Among these advancements, the stainless steel automatic welding machine emerges as a linchpin in modern manufacturing—offering enhanced efficiency, precision, and durability.

Another significant advantage of automatic welding machines is their contribution to enhanced workplace safety. Welding, by nature, involves high temperatures, intense light, and hazardous fumes—all of which can pose risks to human operators. Automating the welding process minimizes direct human exposure to these hazards, thus aligning with stringent industrial safety standards. Machines can operate in controlled environments, ensuring both the safety of human workers and the protection of sensitive material properties. The expertise behind the design and manufacturing of these machines comes from years of research and a deep understanding of both material science and robotic engineering. Companies producing stainless steel automatic welding machines typically invest heavily in research and development to stay on the cutting edge of technology, maintaining their reputation as industry leaders. Their commitment to innovation cements their authority not only in welding solutions but also in broader manufacturing advancements. Moreover, these machines are not static; they evolve with market needs. As industries increasingly focus on sustainability and resource efficiency, automatic welding machines are being designed to minimize energy consumption and maximize material utilization, reducing the overall carbon footprint. This commitment to environmental stewardship is another reason why manufacturers can trust these machines to meet both current and future demands. In conclusion, the stainless steel automatic welding machine is more than just a piece of equipment; it is a testament to the advances in technology that continue to propel industries forward. Its blend of experience, expertise, authoritativeness, and trustworthiness makes it an invaluable asset in modern manufacturing. For those invested in quality, safety, and efficiency, this technology not only represents a worthwhile investment but a pivotal component in the pursuit of perfection in metal joining procedures.

Another significant advantage of automatic welding machines is their contribution to enhanced workplace safety. Welding, by nature, involves high temperatures, intense light, and hazardous fumes—all of which can pose risks to human operators. Automating the welding process minimizes direct human exposure to these hazards, thus aligning with stringent industrial safety standards. Machines can operate in controlled environments, ensuring both the safety of human workers and the protection of sensitive material properties. The expertise behind the design and manufacturing of these machines comes from years of research and a deep understanding of both material science and robotic engineering. Companies producing stainless steel automatic welding machines typically invest heavily in research and development to stay on the cutting edge of technology, maintaining their reputation as industry leaders. Their commitment to innovation cements their authority not only in welding solutions but also in broader manufacturing advancements. Moreover, these machines are not static; they evolve with market needs. As industries increasingly focus on sustainability and resource efficiency, automatic welding machines are being designed to minimize energy consumption and maximize material utilization, reducing the overall carbon footprint. This commitment to environmental stewardship is another reason why manufacturers can trust these machines to meet both current and future demands. In conclusion, the stainless steel automatic welding machine is more than just a piece of equipment; it is a testament to the advances in technology that continue to propel industries forward. Its blend of experience, expertise, authoritativeness, and trustworthiness makes it an invaluable asset in modern manufacturing. For those invested in quality, safety, and efficiency, this technology not only represents a worthwhile investment but a pivotal component in the pursuit of perfection in metal joining procedures.

Prev:

Latest News

-

The Rise of Laser Welding in Global Manufacturing: Spotlight on China’s Competitive EdgeNewsJun.05,2025

-

The Power of Precision: Exploring the Role of Automatic Seam Welding Machines in Modern ManufacturingNewsJun.05,2025

-

The Essential Guide to Can Welding Machines: Revolutionizing the Packaging IndustryNewsJun.05,2025

-

Resistance Welding Equipment: A Smart Investment for Industrial ManufacturingNewsJun.05,2025

-

Precision Welding for Modern Manufacturing: The Rise of Automatic Seam Welding MachinesNewsJun.05,2025

-

Laser Welding for Stainless Steel: The Precision Edge in Modern Metal FabricationNewsJun.05,2025

-

The Modern Evolution of Barrel Production: Technology, Machines, and Market PricingNewsMay.22,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024