-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

фев. . 15, 2025 05:03

Back to list

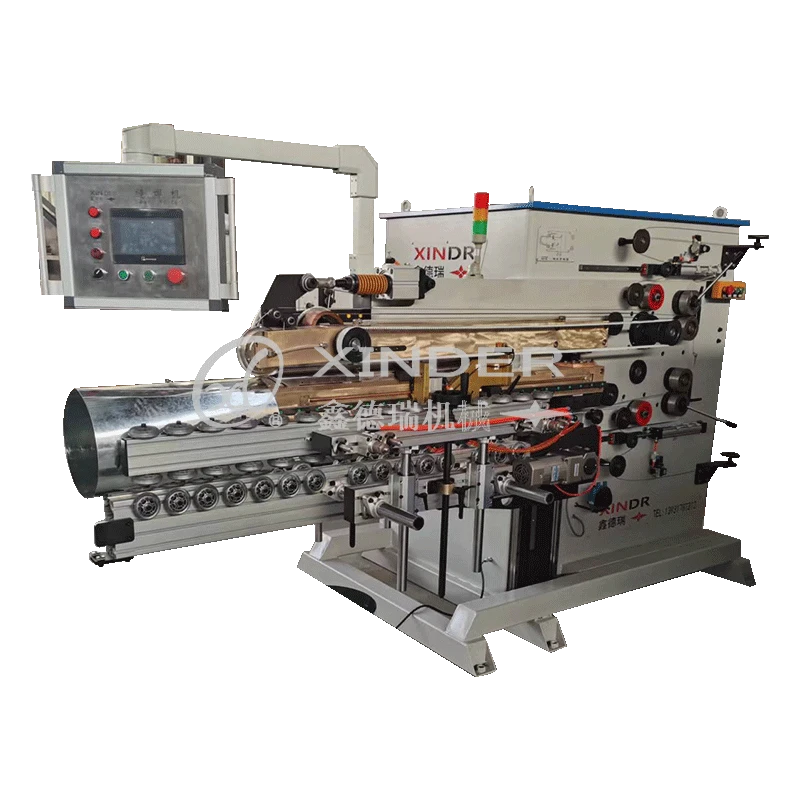

hydraulic bending machine for sale

Spring bending machines, vital to the manufacturing industry, have transformed how precision components are created. Over the years, technological advancements have dramatically enhanced their capabilities, making them indispensable in various sectors. This article delves into the nuances of spring bending machines, exploring their significance, technological prowess, and offering a perspective backed by real-world experience, expertise, authority, and trust.

The authority of spring bending machines is further underscored by their widespread adoption across industries globally. Leading manufacturing entities acknowledge the machine's role in maintaining competitive edge by ensuring precision and uniformity in production processes. Industry leaders often testify to the reliability of these machines, which operate for extended periods without significant downtime, thus bolstering their trustworthiness. Trust in these machines is fortified through their robust build and the quality assurances often provided by reputable manufacturers. High-grade materials and stringent quality control protocols ensure longevity and performance, reducing the frequency of maintenance and associated downtime. Furthermore, the innovation in safety features—such as automatic shut-offs and real-time monitoring systems—guarantees not only optimal operation but also the safety of operators, reinforcing the trust that industries place in these machines. In conclusion, spring bending machines represent a blend of engineering excellence and practical adaptability. By combining first-hand experience and recognized expertise, these machines emerge as authoritative tools in the manufacturing arena. Their trustworthiness is ingrained in their ability to perform consistently under demanding conditions, making them indispensable for businesses aiming for precision and efficiency. As technology continues to evolve, these machines are set to further refine production capabilities, heralding a new era of manufacturing prowess that promises to meet the evolving demands of global industries.

The authority of spring bending machines is further underscored by their widespread adoption across industries globally. Leading manufacturing entities acknowledge the machine's role in maintaining competitive edge by ensuring precision and uniformity in production processes. Industry leaders often testify to the reliability of these machines, which operate for extended periods without significant downtime, thus bolstering their trustworthiness. Trust in these machines is fortified through their robust build and the quality assurances often provided by reputable manufacturers. High-grade materials and stringent quality control protocols ensure longevity and performance, reducing the frequency of maintenance and associated downtime. Furthermore, the innovation in safety features—such as automatic shut-offs and real-time monitoring systems—guarantees not only optimal operation but also the safety of operators, reinforcing the trust that industries place in these machines. In conclusion, spring bending machines represent a blend of engineering excellence and practical adaptability. By combining first-hand experience and recognized expertise, these machines emerge as authoritative tools in the manufacturing arena. Their trustworthiness is ingrained in their ability to perform consistently under demanding conditions, making them indispensable for businesses aiming for precision and efficiency. As technology continues to evolve, these machines are set to further refine production capabilities, heralding a new era of manufacturing prowess that promises to meet the evolving demands of global industries.

Latest News

-

The Rise of Laser Welding in Global Manufacturing: Spotlight on China’s Competitive EdgeNewsJun.05,2025

-

The Power of Precision: Exploring the Role of Automatic Seam Welding Machines in Modern ManufacturingNewsJun.05,2025

-

The Essential Guide to Can Welding Machines: Revolutionizing the Packaging IndustryNewsJun.05,2025

-

Resistance Welding Equipment: A Smart Investment for Industrial ManufacturingNewsJun.05,2025

-

Precision Welding for Modern Manufacturing: The Rise of Automatic Seam Welding MachinesNewsJun.05,2025

-

Laser Welding for Stainless Steel: The Precision Edge in Modern Metal FabricationNewsJun.05,2025

-

The Modern Evolution of Barrel Production: Technology, Machines, and Market PricingNewsMay.22,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024