-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

фев. . 16, 2025 10:47

Back to list

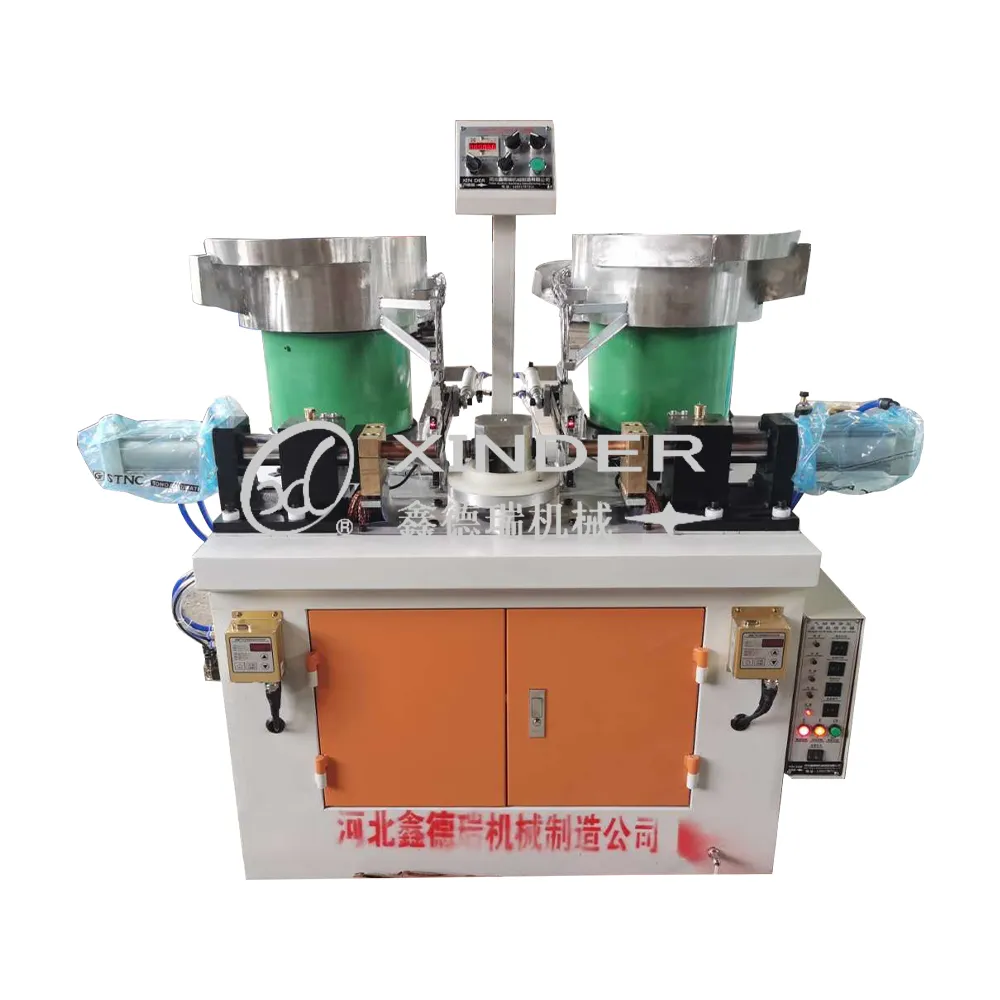

Fully Automatic Welded Pipe Machine

High frequency pipe welding machines have emerged as indispensable tools in the metal fabrication industry. These machines, renowned for their precision and efficiency, utilize high-frequency currents to weld pipes with unmatched speed and consistency. This article seeks to delve into the multifaceted advantages of high frequency pipe welding machines, reinforcing their standing in the market through real-world experiences, technical expertise, and authoritative endorsements.

Authoritative bodies in the welding industry, such as the American Welding Society (AWS), have recognized the role of high frequency pipe welding machines in advancing welding standards. Their acknowledgment serves as a benchmark for quality and reliability, dispelling any skepticism about the technology's capability. Products that meet or exceed these standards are often considered top-tier, providing an additional layer of assurance to potential buyers. Trustworthiness is further established through real-world testimonies and case studies. Many companies have documented their successful transition from conventional welding methods to high frequency welding, often citing a significant improvement in product quality and overall production costs. For instance, a pipe manufacturing plant recorded a 30% increase in production volume with the adoption of high frequency welding machines. Such testimonials from reputable sources are compelling due to their first-hand nature and quantifiable results, demonstrating both the reliability and effectiveness of the machines. In conclusion, high frequency pipe welding machines are critical in modern metal fabrication, delivering consistent, high-quality welds that meet industry standards. Their ability to streamline operations while maintaining peak performance makes them a desirable choice for manufacturers looking to enhance productivity and reduce costs. Accredited training ensures operators can handle these sophisticated machines effectively, making the technology accessible and reliable. Endorsements from authoritative organizations further cement their status as leaders in the field. Real-world success stories amplify trust, positioning high frequency pipe welding machines as indispensable assets in contemporary industrial applications.

Authoritative bodies in the welding industry, such as the American Welding Society (AWS), have recognized the role of high frequency pipe welding machines in advancing welding standards. Their acknowledgment serves as a benchmark for quality and reliability, dispelling any skepticism about the technology's capability. Products that meet or exceed these standards are often considered top-tier, providing an additional layer of assurance to potential buyers. Trustworthiness is further established through real-world testimonies and case studies. Many companies have documented their successful transition from conventional welding methods to high frequency welding, often citing a significant improvement in product quality and overall production costs. For instance, a pipe manufacturing plant recorded a 30% increase in production volume with the adoption of high frequency welding machines. Such testimonials from reputable sources are compelling due to their first-hand nature and quantifiable results, demonstrating both the reliability and effectiveness of the machines. In conclusion, high frequency pipe welding machines are critical in modern metal fabrication, delivering consistent, high-quality welds that meet industry standards. Their ability to streamline operations while maintaining peak performance makes them a desirable choice for manufacturers looking to enhance productivity and reduce costs. Accredited training ensures operators can handle these sophisticated machines effectively, making the technology accessible and reliable. Endorsements from authoritative organizations further cement their status as leaders in the field. Real-world success stories amplify trust, positioning high frequency pipe welding machines as indispensable assets in contemporary industrial applications.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024