-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

የካቲ . 12, 2025 18:12

Back to list

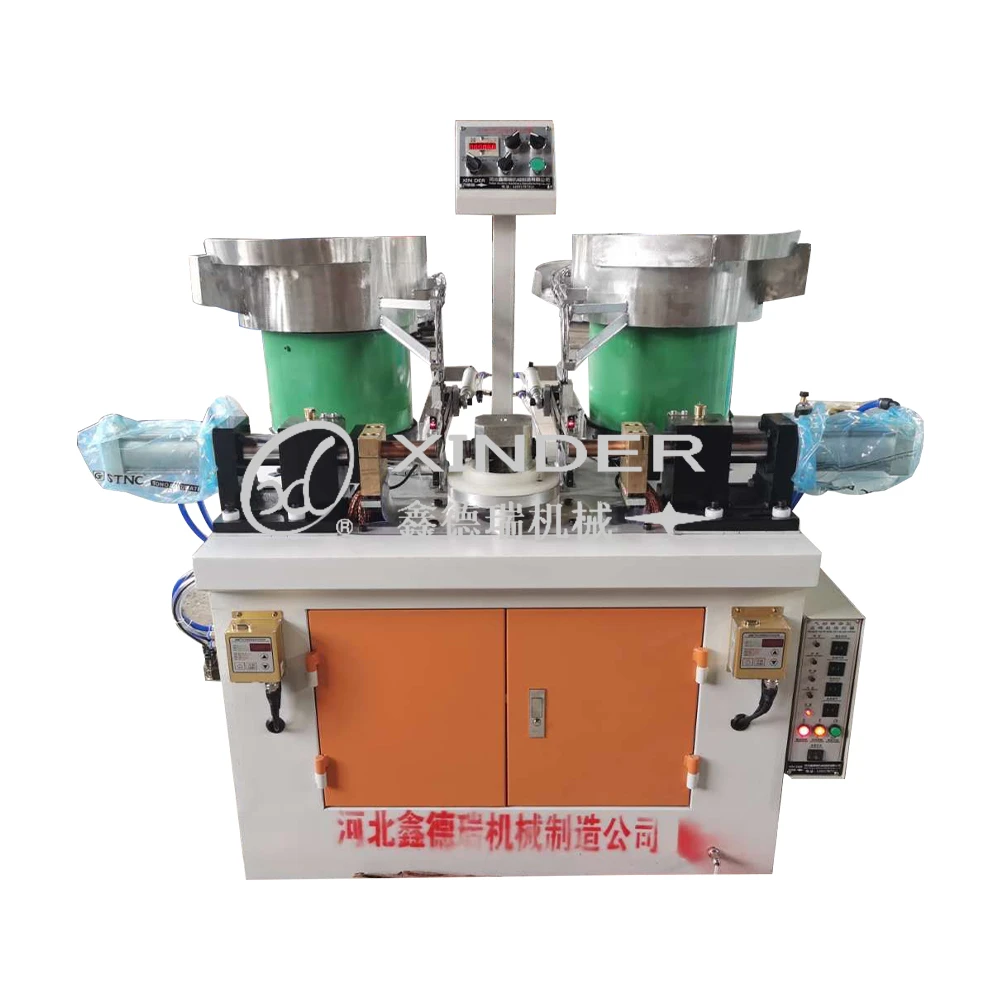

angle iron bending machine

The evolving landscape of metalworking brings forth various tools essential for precision and efficiency. Among these, the angle iron bending machine stands out as a quintessential tool in transforming raw materials into structured, versatile components. This article delves into the unparalleled attributes of angle iron bending machines, emphasizing their indispensable role in enhancing productivity and precision in metalworking.

Furthermore, the automation and precision offered by angle iron bending machines translate to enhanced safety in the workplace. Manual bending processes pose significant risks of injury due to mishandling of heavy materials or equipment operation errors. By automating the bending process, these machines minimize direct human interaction with potentially dangerous equipment, thereby preventing accidents and promoting a safer working environment. Expertise in operating angle iron bending machines necessitates a comprehensive understanding of their software and hardware components. Training operators to proficiently manage these machines contributes significantly to productivity. Experienced operators can swiftly identify and rectify any issues, ensuring the smooth functioning of the machine, thereby reducing downtime and maintaining production schedules. Trust in angle iron bending machines stems from their proven track record in various industries. From construction and automotive to shipbuilding, these machines have demonstrated their versatility and efficacy, consistently producing high-quality components. Industry professionals acknowledge the machines' ability to deliver precise results rapidly, reinforcing their reputation as vital assets in metalworking. In conclusion, angle iron bending machines represent a significant advancement in metalworking technology. Their precision, adaptability, durability, and contribution to workplace safety underscore their value in industrial operations. As industries continue to evolve, these machines will undoubtedly remain pivotal in enhancing production efficiency and ensuring the structural integrity of metal frameworks. For professionals seeking to optimize their metalworking processes, investing in high-quality angle iron bending machines is a strategic decision that promises substantial returns in both performance and productivity.

Furthermore, the automation and precision offered by angle iron bending machines translate to enhanced safety in the workplace. Manual bending processes pose significant risks of injury due to mishandling of heavy materials or equipment operation errors. By automating the bending process, these machines minimize direct human interaction with potentially dangerous equipment, thereby preventing accidents and promoting a safer working environment. Expertise in operating angle iron bending machines necessitates a comprehensive understanding of their software and hardware components. Training operators to proficiently manage these machines contributes significantly to productivity. Experienced operators can swiftly identify and rectify any issues, ensuring the smooth functioning of the machine, thereby reducing downtime and maintaining production schedules. Trust in angle iron bending machines stems from their proven track record in various industries. From construction and automotive to shipbuilding, these machines have demonstrated their versatility and efficacy, consistently producing high-quality components. Industry professionals acknowledge the machines' ability to deliver precise results rapidly, reinforcing their reputation as vital assets in metalworking. In conclusion, angle iron bending machines represent a significant advancement in metalworking technology. Their precision, adaptability, durability, and contribution to workplace safety underscore their value in industrial operations. As industries continue to evolve, these machines will undoubtedly remain pivotal in enhancing production efficiency and ensuring the structural integrity of metal frameworks. For professionals seeking to optimize their metalworking processes, investing in high-quality angle iron bending machines is a strategic decision that promises substantial returns in both performance and productivity.

Prev:

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024