-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 11, 2025 12:14

Back to list

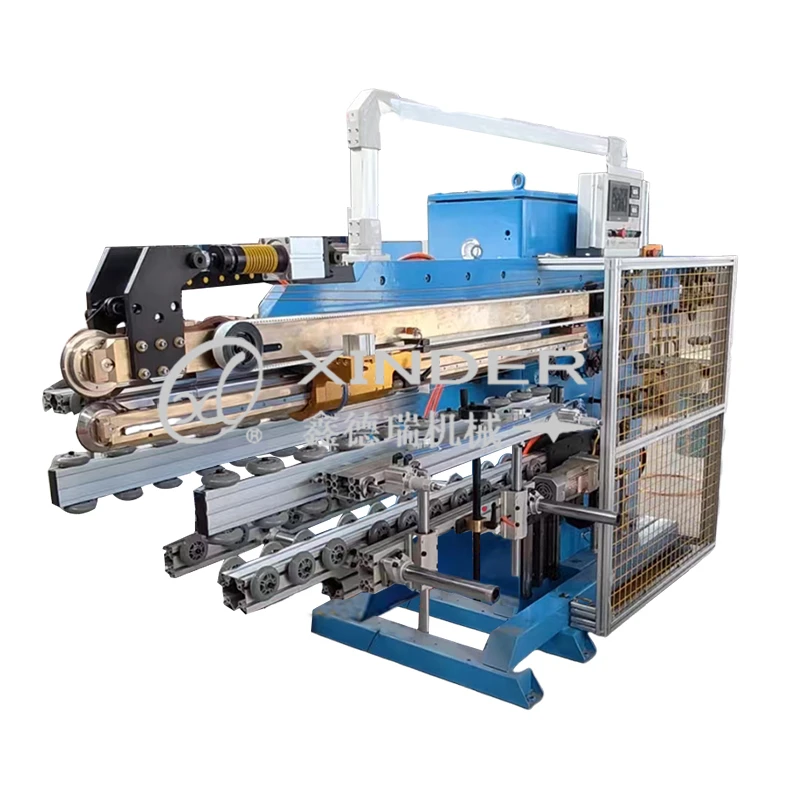

motorised pipe bending machine

In the world of modern manufacturing and construction, the motorised pipe bending machine stands as an epitome of efficiency and precision. Companies that fabricate piping systems, structural frameworks, and even automotive parts, often find themselves in need of versatile and reliable pipe bending solutions that can match the demands of increasingly complex projects. Motorised pipe bending machines offer an unparalleled advantage in terms of speed, accuracy, and consistency, critical facets that shape the productivity and profitability of industries reliant on high-quality bent pipes.

From an expertise perspective, manufacturers of motorised pipe bending machines invest heavily in research and development to stay ahead of technological advancements. This commitment to innovation ensures that they can offer machines with enhanced features such as multi-radius bending, quick-change tooling, and environmental efficiency. The latter is particularly relevant in today’s market where environmental responsibility is not just a preference but a requirement. When considering authoritative sources, industry leaders in pipe bending technology provide extensive documentation, training, and after-sales support to ensure every customer can achieve optimal performance from their machine. This empowers businesses to not only get the most out of their investment but also paves the way for new applications in fields they previously could not compete in due to technological limitations. Trustworthiness, another critical attribute in the selection of capital-intensive machinery, is evidenced by the robust warranties and service agreements offered by leading manufacturers. This demonstrates a confidence in their products and a commitment to ongoing customer satisfaction, offering peace of mind by protecting businesses from unexpected breakdowns and associated downtimes. Overall, the motorised pipe bending machine is more than just a manufacturing tool; it’s a cornerstone of industrial success in a world increasingly leaning towards automation and precision. Its ability to revolutionise processes, improve product quality, and enhance profitability is unmatched, making it an essential acquisition for businesses aiming to maintain a competitive edge.

From an expertise perspective, manufacturers of motorised pipe bending machines invest heavily in research and development to stay ahead of technological advancements. This commitment to innovation ensures that they can offer machines with enhanced features such as multi-radius bending, quick-change tooling, and environmental efficiency. The latter is particularly relevant in today’s market where environmental responsibility is not just a preference but a requirement. When considering authoritative sources, industry leaders in pipe bending technology provide extensive documentation, training, and after-sales support to ensure every customer can achieve optimal performance from their machine. This empowers businesses to not only get the most out of their investment but also paves the way for new applications in fields they previously could not compete in due to technological limitations. Trustworthiness, another critical attribute in the selection of capital-intensive machinery, is evidenced by the robust warranties and service agreements offered by leading manufacturers. This demonstrates a confidence in their products and a commitment to ongoing customer satisfaction, offering peace of mind by protecting businesses from unexpected breakdowns and associated downtimes. Overall, the motorised pipe bending machine is more than just a manufacturing tool; it’s a cornerstone of industrial success in a world increasingly leaning towards automation and precision. Its ability to revolutionise processes, improve product quality, and enhance profitability is unmatched, making it an essential acquisition for businesses aiming to maintain a competitive edge.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024